Coating to Prevent Plasticizer Leaching in Medical Devices

A novel PTL/SA coating shows good performance and low cost for preventing phthalate leaching in medical devices and food packaging.

Phthalate is a widely used plasticizer, with di-(2-ethylhexyl phthalate) (DEHP) being the most common type of phthalate. Because it does not chemically bond to plastic matrices, phthalate has a known risk of leaching into the environment. This can cause adverse health effects, such as reproductive system problems and infertility in women. Nevertheless, medical devices—which require additional considerations for interactions with drugs—and food packaging commonly contain it. Because of this, preventing the migration of phthalates in plastics is a challenge of immense importance. Researchers are investigating various strategies to inhibit the migration of plasticizers, including a novel dip coating.

You can also read: Leachables in Medical Plastics – What’s The Issue?

A Protein Coating to Prevent Leaching

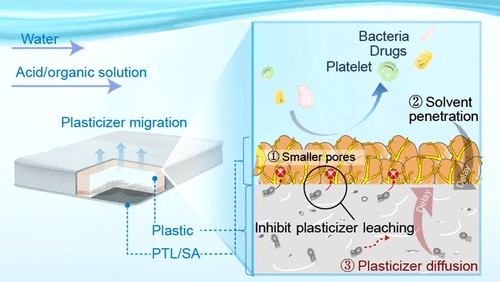

To create an amyloid-like protein coating on plastics, researchers utilized phase-transitioned lysozyme (PTL). The rapid, amyloid-like aggregation of lysozyme formed a dense layer of biopolymer nanoparticles on the plastic’s surface. Researchers effectively incorporated the PTL with sodium alginate (SA), resulting in a PTL/SA coating. This ~210 nm coating showed stable adhesion properties and excellent resistance to active substance adsorption.

The PTL/SA coating inhibited plasticizer leaching and showed good biocompatibility, suggesting a potential replacement for conventional medical coatings. Courtesy of Amyloid-Like Protein Coating as a Barrier Against Plasticizer Leaching.

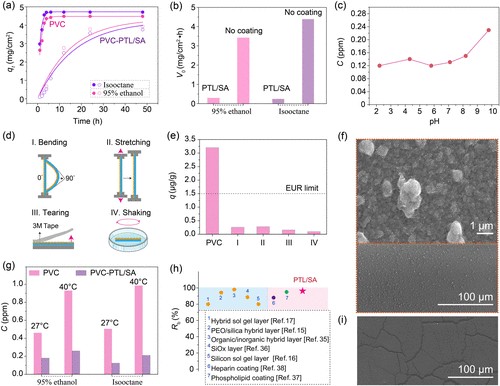

Researchers employed UV-vis spectroscopy to assess the migration of dioctyl phthalate (DOP) and DEHP. They compared the absorption values at 275 nm between coated and uncoated plastic film. A dialysis tube, infusion tube, and blood bag were the representative PVC medical plastics used in this experiment. Typically, internal voids in bulk materials allow for plasticizer diffusion. Densely packed protein oligomer nanoparticles comprise the PTL/SA coating voids. Introducing SA into the PTL reduced the pore size of the coating from ~2 nm to 1.3 nm. The molecular sizes of DEHP and DOP are 1.6 and 1.5, respectively. Thus, the coating should prevent their leaching. When tested and compared to uncoated plastics, the coating reduced plasticizer concentrations in the contact medium by ~92%.

Solvent composition can contribute significantly to plasticizer migration. Therefore, researchers exposed the coating to neutral, acidic, and weakly alkaline solutions for 10 days. The PTL coating remained stable due to the superior adhesion and chemical stability provided by the protein film’s amyloid-like structure.

Researchers conducted various tests to evaluate the PTL/SA coating under different usage conditions. Courtesy of Amyloid-Like Protein Coating as a Barrier Against Plasticizer Leaching.

Barrier-Efficient and Cost-Effective Solution for Plasticizer Leaching

The PTL/SA coating showed improved barrier efficiency compared to commercial medical coatings. Its barrier efficiency was similar to that of an oxide coating, but PTL/SA showed better performance for temperature-sensitive plastics. Additionally, preparation of the coating is simple and adaptable to large-scale applications. The production cost is significantly less than that of the traditional heparin sodium coating used in medical applications. This coating can reduce leaching in PVC, PE, PET, PC, and PP over 7-1000 times, even under harsh environments.