Multi-State EPR Compliance: Packaging Design Under Pressure

EPR laws across US states apply different material definitions, recyclability criteria, and PCR targets, making packaging design a key factor in determining compliance fees.

In 2025, Extended Producer Responsibility (EPR) for packaging entered the US market. But unlike Europe’s harmonized systems, the US EPR landscape continues to evolve into a patchwork of state-specific requirements.

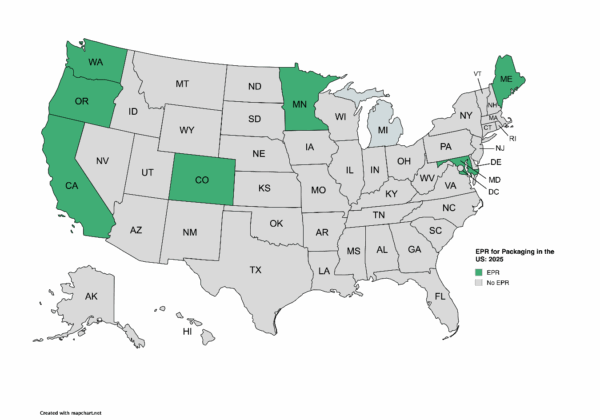

California, Oregon, Colorado, Maine, and Minnesota already enforce detailed EPR laws. Maryland and Washington joined them in May 2025. More states are drafting new rules, each adding its own twist. Companies that ship products nationwide must now handle conflicting legal definitions, material categories, data systems, and fee structures.

You can also read: Understanding Extended Producer Responsibility (EPR).

Understanding the Fragmented Landscape

The US EPR Landscape in 2025. Courtesy of Packaging School.

At first glance, many state EPR laws seem similar. But under the surface, engineers face divergent definitions of “producer” and “covered materials,” varied targets for recycling and PCR content, and complex eco-modulation schemes that directly tie design decisions to financial penalties or rewards.

- California SB 54 requires producers to register with a Producer Responsibility Organization by April 2025. Packaging data reporting starts August 2025. The law mandates 65% recycling of single-use plastics and 25% source reduction by 2032.

- Oregon’s Plastic Pollution and Recycling Modernization Act takes full effect July 1, 2025, with reports due as early as March 2025. Oregon’s system ties payments to recyclers and municipalities based on recyclability scores.

- Colorado’s Statewide Recycling Act demands data reporting and fees beginning in 2025 and 2026, respectively.

- Maine, Maryland, Washington, and Minnesota each add their own definitions, timelines, and material lists, complicating national compliance strategies.

For engineers, these laws highlight the importance of packaging attributes, from material type to label adhesive, and their impact on both recyclability and EPR fees.

Eco-Modulation

Unlike flat fees, most EPR programs incorporate eco-modulation. This is a system that adjusts fees based on packaging design features. Materials that are easier to recycle, containing PCR content, or free of contaminants generally carry lower fees.

In Oregon, for example, PRO payments reflect recyclability assessments. California’s system penalizes hard-to-recycle formats like multi-material laminates. PET, HDPE, and PP often qualify for favorable rates if designed properly.

Every design feature becomes a cost driver. The APR Design Guide offers a valuable technical reference to align packaging designs with recyclability standards likely to influence fee calculations.

Designing for PCR Integration

EPR frameworks are also integrating with PCR mandates. California’s AB 793 requires beverage containers to reach 25% PCR by 2025 and 50% by 2030. Colorado aims for 30% PCR in PET packaging by 2030. Other states are likely to follow.

Incorporating PCR presents engineering challenges:

- Mechanical Performance

PCR resins may exhibit variability in mechanical properties, requiring adjustments in wall thickness, geometry, or additives.

- Food Contact Compliance

FDA-approved PCR grades for food applications remain limited, requiring close coordination with suppliers.

Engineers must develop formulations that maintain performance while integrating increasing PCR content, often through careful blending or modifying processing parameters.

Source Reduction

California’s SB 54 requires a 25% source reduction for plastic packaging and food service ware by 2032. This pushes engineers to lighten packaging, remove redundant layers, and create multipurpose components.

But engineers must balance source reduction with recyclability. Over-light weighting can make films too thin to recover or labels that hinder sorting. A holistic design approach becomes essential.

The Emerging Role of Producer Responsibility Organizations (PROs)

While each state controls its EPR law, several have authorized PROs to coordinate compliance. The Circular Action Alliance now operates in California, Colorado, Oregon, and Minnesota. Membership in multi-state PROs may help companies standardize some aspects of reporting, fee payments, and recycling access.

However, engineers should not assume PRO harmonization simplifies design obligations. Each state still maintains control over recyclability definitions, fee modulation schemes, and performance targets.

Towards a National Design Standard?

With so much complexity, companies follow a “highest common denominator” design strategy. They build packaging to meet the strictest state rules, often those in California and Oregon, to improve compliance across all markets.

This approach shapes engineering choices in:

- Selecting easily recycled resins

- Removing problem additives

- Standardizing label adhesives and inks

- Integrating PCR across product lines

Over time, these design shifts may move the industry toward a functional national standard.

Engineering Leadership in an EPR Era

The stakes keep rising. EPR compliance fees may climb past $4.7 billion by 2026 across active US states. Fee structures now punish hard-to-recycle formats, multilayer films, non-removable labels, and packages without post-consumer recycled content. Packaging that uses readily recyclable materials like PET, HDPE, and PP, when designed to meet APR guidelines, earns lower eco-modulated fees. Adding approved PCR grades and removing problem additives can cut costs even further. As states adjust their fee models, engineering choices on materials, components, and recyclability will directly drive compliance costs in every market.