K 2025 Preview: Game-Changing Plastics Technologies on the Horizon

K 2025 preview unveils cutting-edge plastics tech: low-carbon materials, advanced recycling, smart thermoplastics, and EV-ready polycarbonates.

At the Pre-K 2025 preview in Düsseldorf, global plastics leaders introduced key innovations they plan to showcase at this year’s K Show. Because the industry faces rising sustainability demands, companies emphasized circularity, decarbonization, and smart manufacturing as critical focus areas. Consequently, the technologies presented reflect how manufacturers transform their approaches to meeting performance and environmental goals.

You can also read: K 2025: Driving Innovation Amid Economic Uncertainty.

BASF Advances Circularity with Low-Carbon Plastics

BASF expanded its rPCF product line, using renewable electricity and steam to cut emissions during plastics production. This complements BASF’s ZeroPCF range and helps brand owners reduce their overall carbon footprint across the value chain. Additionally, BASF promotes two circular technologies that help replace virgin feedstocks with renewable or recycled alternatives.

Biomass Balance replaces fossil raw materials with renewable inputs at the beginning of the chemical production process. Ccycled® reprocesses plastic waste through chemical recycling to create new materials identical to those made with virgin resources. Therefore, these solutions now appear in helmets, electrical housings, compostable films, and technical apparel.

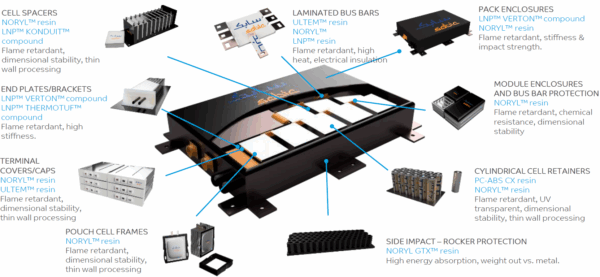

SABIC Empowers Design with Next-Gen Thermoplastics

SABIC introduced advanced thermoplastics designed to increase sustainability and performance across mobility, medical, and electronics applications. These materials provide better design flexibility, higher recyclability, and reduced environmental impact across high-demand industrial sectors. As a result, engineers can use them to design lightweight parts, streamline integration, and embed circular principles into product development. Because industries now seek multifunctional materials, SABIC’s innovations respond to the growing demand for more innovative and sustainable polymers.

SABIC’s advanced thermoplastics for EV mobility – Highlighting innovative materials used in automotive interiors and electrical systems. Courtesy of SABIC.

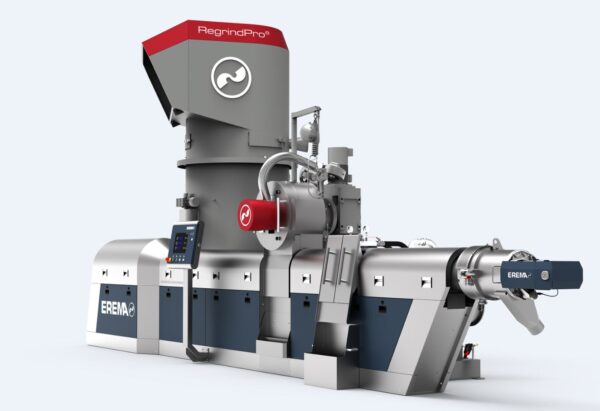

Erema Sets a New Standard in Mechanical Recycling

Erema announced three next-generation recycling systems to improve efficiency and recyclate quality in post-consumer plastic processing. These systems combine real-time process control, digital monitoring, and advanced filtration to achieve high-quality results from mixed waste streams. Erema’s upgrades allow manufacturers to meet stricter standards while incorporating more recycled content into new products.

Erema’s RegrindPro® system delivers high-quality recyclate using digital monitoring and advanced filtration. Courtesy of Erema.

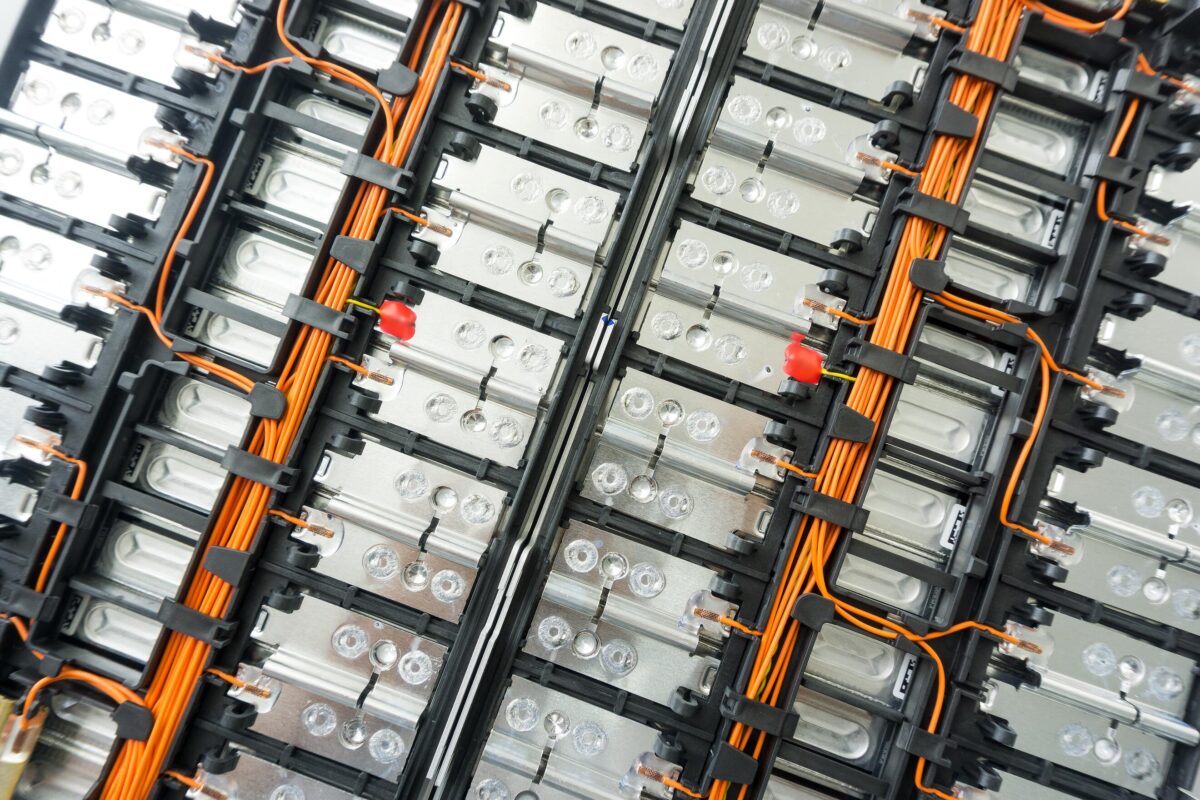

Covestro Unveils Battery-Compatible Polycarbonates

Covestro introduced high-voltage-resistant polycarbonate materials developed for electric vehicles and energy storage system applications.These materials offer excellent insulation, heat resistance, and mechanical strength—critical for use in batteries and electronic modules. Because electrification is expanding rapidly, Covestro’s innovation addresses the need for lightweight, flame-retardant, and electrically stable components.

K 2025: The Future of Plastics Takes Shape

The Pre-K showcase highlighted how the plastics industry is moving quickly toward decarbonization, circularity, and intelligent material design. By investing in low-carbon materials, advanced recycling, and functional polymers, companies are redefining how plastics contribute to a sustainable future. As K 2025 approaches this October, Düsseldorf will host the next chapter in global plastics innovation and transformation.