Certified-Renewable Plastics at Industrial Scale

SABIC, BASF, and Braskem are using certified-renewable plastics to reshape supply chains with drop-in, low-carbon, ISCC PLUS-certified solutions.

You can also read: Perstorp’s New PVC Plasticizer Based on Renewable Carbon Content.

Big-League Renewable Feedstock Adopters Step Forward

- SABIC’s 2019 launch of ISCC PLUS-certified renewable polycarbonate (Lexan™) marked a turning point in sustainable materials innovation globally.

Produced using second-generation tall-oil feedstock through a mass-balance method, it slashes CO₂ emissions by 61% and fossil depletion by 35%.

Manufactured in Bergen op Zoom and Cartagena, this resin fits seamlessly into existing production, reinforcing SABIC’s TRUCIRCLE™ circularity commitment. - BASF replaced fossil content in ecoflex® F Blend C1200 BMB with waste-based biomass certified under the ISCC PLUS and REDcert2 programs.

Their product cuts carbon footprint by 60% while maintaining identical properties, allowing businessehttps://www.sabic.com/en/news/21603-sabic-first-in-industry-to-launch-polycarbonate-based-on-certified-renewable-feedstocks to adopt it without modifying operations. - Braskem, a leader in Latin America, uses ISCC PLUS and Bonsucro-certified sugarcane ethanol to create Green PE and Green Ethylene.

Each kilogram produced at Triunfo’s 200,000-ton/year facility sequesters 2.15 kg of CO₂, offering climate benefits at an industrial scale.

Partnerships with Neste and Shell now support Wenew-labeled PP and PE using renewable and recycled sources in South America.

What Breweries, Packaging, and Auto Makers Should Notice

| Criterion | SABIC PC | BASF ecoflex® BMB | Braskem Green PE |

|---|---|---|---|

| Feedstock Type | Forest by-product | Waste biomass | Sugarcane ethanol |

| Certifications | ISCC PLUS | ISCC PLUS, REDcert2 | ISCC PLUS, Bonsucro |

| CO₂ Reduction | ~60% | ~60% | 2.15 kg CO₂/kg |

| Production Scale | Global | Packaging industry | 200 kt/year |

| Drop-in Ready | Yes | Yes | Yes |

All three giants use mass-balance approaches to ensure quality, compatibility, and certified sustainability—without disrupting supply chain operations.

Perspective: Why the Momentum Matters Now

SABIC, BASF, and Braskem are transforming plastics using certified-renewable inputs, showing how sustainability and scale can align perfectly.

Their strategies combine chain-of-custody certification, life cycle data, and drop-in readiness—making bio-feedstock a real-world business solution.

As regulations tighten and public expectations grow, the mass-balance model is fast becoming the global gold standard for transformation.

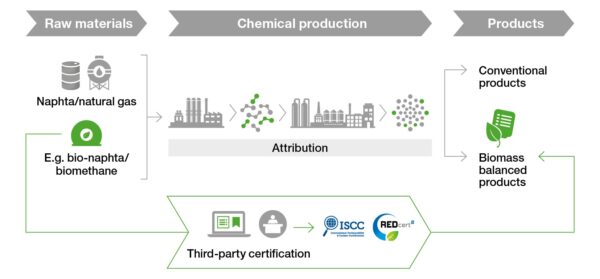

Biomass Balance: A practical approach to reduce the dependency on fossil feedstock. Courtesy of BASF.

From Compliance to Strategic Preference

Certified-renewable materials have become central to procurement decisions, increasingly guided by ESG frameworks and investor-driven climate goals. Companies are no longer focused solely on compliance—they are now treating sustainability as a strategic differentiator, particularly in industries like consumer goods, technology, and automotive.

For example, Apple and HP have begun integrating renewable or recycled polycarbonate into their devices, aligning with both emissions targets and rising expectations for supply chain transparency.

You can also read: Apple’s New iPhone Packaging: A Sustainable Shift?

In the packaging sector, Unilever and Nestlé are actively sourcing ISCC PLUS or Bonsucro-certified materials to support their environmental commitments and meet consumer demand for credible sustainability claims. Meanwhile, automotive leaders like Volkswagen and BMW are incorporating bio-based polymers into vehicle interiors, achieving EU emissions standards without compromising product performance or design integrity.

These developments highlight how certifications such as ISCC PLUS do more than validate carbon reductions—they also help ensure ethical labor practices, responsible land use, and full traceability throughout the material lifecycle.

Market Outlook and Investment Trends

Bio-based plastic demand is expected to double by 2029, with growth driven by tightening regulations and rising investor pressure. EU policies like the Packaging and Packaging Waste Regulation now mandate renewable content, while frameworks such as TCFD and CDP demand full material transparency. In response, industry leaders like BASF, SABIC, and Braskem are scaling up investments, positioning themselves as ESG-aligned partners—not just suppliers. Together, these forces are redefining the plastics industry around sustainability, traceability, and long-term accountability.