Boosting Biodegradable Packaging with PLA/Nanoclay/ZnO Films

Smart nanocomposites based on PLA and ZnO push bioplastics closer to real-world performance, offering strength, thermal stability, and sustainability in one simple film.

As demand for eco-friendly options increases, scientists are working on new biodegradable materials for packaging. A recent study shows that adding nanoclay and zinc oxide (ZnO) nanoparticles to PLA films can improve strength and heat resistance, making them a promising green alternative for industrial packaging.

You can also read: Modifying the Slip of Plastic Films with Additives

Why Reinforce PLA?

PLA, a biobased polyester produced from renewable sources like corn starch, stands out as an eco-friendly plastic option. It offers several advantages, including biodegradability and reduced carbon footprint. However, its mechanical strength, barrier properties, and thermal stability often fall short compared to conventional petroleum-based plastics. These limitations restrict PLA’s use in demanding applications such as industrial and food packaging. Incorporating nanoclay and ZnO nanoparticles into the PLA matrix addresses these challenges by enhancing durability, thermal resistance, and overall performance without sacrificing biodegradability.

A Simple, Energy-Efficient Process

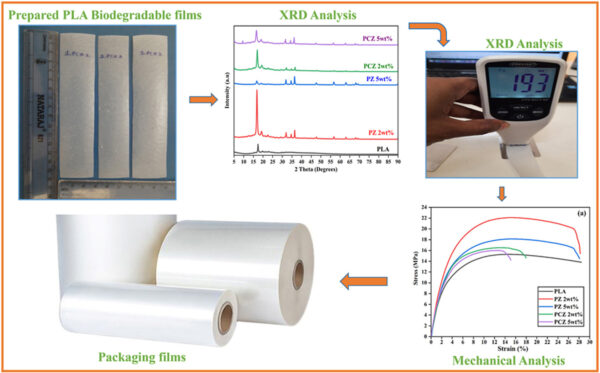

Graphical abstract. Courtesy of Development of biodegradable PLA/Nanoclay/ZnO polymer films for future Industrial packaging applications.

Researchers prepared nanocomposite films using solvent casting at room temperature, and they employed a low-cost applicator for uniform thickness.Since this method avoids high-temperature extrusion and surface treatments, it offers a scalable, energy-efficient approach for industrial and academic use. Moreover, the team developed formulations containing 2 wt% and 5 wt% ZnO and nanoclay to investigate filler effects on film properties.

Surface Morphology and Dispersion

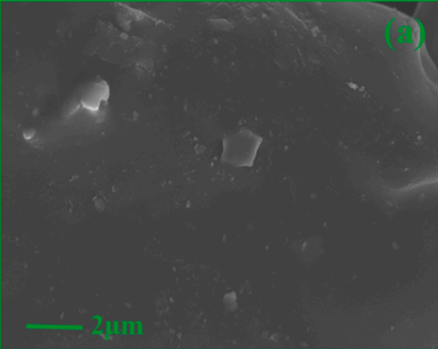

Scanning electron microscopy revealed that nanoparticle dispersion plays a critical role in film performance. At 2 wt% filler loading, ZnO nanoparticles dispersed uniformly within the PLA matrix, creating smooth, defect-free films. This uniform distribution improved stress transfer across the material. However, increasing filler content to 5 wt% led to nanoparticle aggregation, forming clusters that disrupted the film’s continuity and weakened mechanical performance. Managing filler dispersion remains a key factor for achieving optimal material properties in PLA nanocomposites.

Surface morphology of PLA/ZnO at 2 wt%. Courtesy of Development of biodegradable PLA/Nanoclay/ZnO polymer films for future Industrial packaging applications.

Thermal and Structural Properties

X-ray diffraction analysis confirmed that adding ZnO and nanoclay did not significantly alter the crystalline structure of PLA. Characteristic peaks for ZnO appeared clearly, verifying the successful integration of nanoparticles without chemical degradation. Thermal analysis showed that the films maintained stability up to 300°C, with a glass transition temperature near 65°C and a melting point around 160°C. The presence of 2 wt% ZnO nanoparticles delayed thermal decomposition, acting as a thermal barrier that slowed down material degradation under heat.

Mechanical Performance

Tensile tests conducted according to ASTM D882 standards demonstrated notable improvements in mechanical properties at 2 wt% nanoparticle loading. The tensile strength of the films reached 22 MPa, while yield strength peaked at 11 MPa. These enhancements resulted from strong interfacial bonding between ZnO nanoparticles and the PLA chains, facilitating better load distribution under stress. At 5 wt% filler content, mechanical performance declined due to particle aggregation, underscoring the importance of optimizing filler concentrations for maximum benefit.

Towards Stronger, Greener Packaging Solutions

PLA/Nanoclay/ZnO films offer a promising pathway for the next generation of sustainable packaging materials. With improved durability, thermal resistance, and potential antibacterial benefits thanks to the ZnO component, these films target high-demand sectors such as food packaging, where material strength and hygiene are critical.

The easy production method, along with robust performance even at low nanoparticle levels, makes these materials suitable for large-scale use. Future studies will work on improving how nanoparticles spread at higher concentrations and testing how the films break down in real-world conditions. Studying long-term degradation is key to confirming the eco-friendly benefits of these bioplastic composites.

PLA/nanoclay/ZnO films offer an affordable, high-performance, and eco-friendly solution, bringing us closer to sustainable plastics that meet industry needs. By carefully engineering materials at the nanoscale, this research shows that plastics can be both green and high-performing—without sacrificing strength or functionality.