The Challenge and Promise of Nylon 66 Recycling

Technological breakthroughs promise to revolutionize nylon recycling and drive material circularity across industries.

Global production of nylon 66 reaches nearly 4 million tonnes each year. It is widely used in performance apparel and industrial sectors. However, almost two-thirds of textile waste is incinerated in landfills, and less than 1% is recycled. The complex chemical structure of nylon makes recycling difficult, leading to high environmental impacts and continued reliance on virgin plastics from fossil fuels.

You can also read: Nylon Replacing Metal Won an SPE Automotive Award.

Fortunately, a new wave of innovation is changing this landscape. Regulations and consumer demand for sustainability drive the need for carbon reduction and plastic waste minimization. Companies are pioneering recycling solutions, including chemical and enzymatic processes. These new technologies redefine nylon’s role in a circular economy by offering promising pathways for effective recycling.

Toray Industries Innovates in Chemical Recycling of Nylon 66

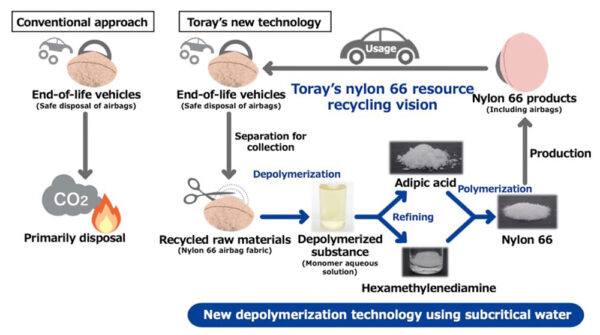

Toray Industries is leading in chemical recycling through a water-based innovation that uses subcritical water to break down nylon 66. This state of water exists at high temperature and pressure, just below the critical point, enabling efficient depolymerization. Their method precisely controls reactions to suppress unwanted side products and recover hexamethylenediamine and adipic acid at high yields. These monomers are then polymerized into high-quality nylon 66 that matches virgin material.

The demand for nylon 66 is around 100,000 metric tons annually in Japan and 1.3 million tons worldwide. Applications include automotive textiles such as airbags, tire cords, and plastic components like radiator tanks and oil pans. Tighter recycling regulations in Japan have made collecting nylon 66-based products mandatory, making chemical recycling more attractive.

Toray’s technology cuts carbon dioxide emissions by half compared with petroleum-based production, supporting carbon reduction targets. The company aims to focus first on automotive materials. They plan to verify quality by 2025 and achieve full-scale mass production around 2030. This initiative supports the Toray Group Sustainability Vision for 2050, which emphasizes sustainable resource management and carbon neutrality.

Samsara Eco Advances Enzymatic Recycling of Nylon 6 and Nylon 66

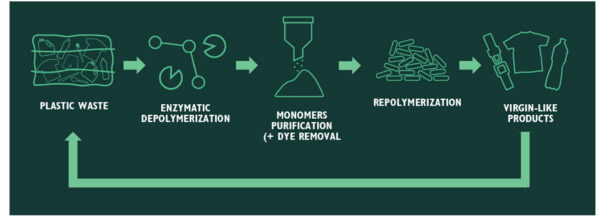

While Toray leverages chemical processes, Samsara Eco turns to biological solutions. Their EosEco platform uses specially designed enzymes to break down nylon 6 and nylon 66 effectively.

These enzymes can recycle mixed fibers, colored textiles, dyed materials, and fabrics blended with spandex, without losing material quality. Their innovation arrives when almost all synthetic textiles are still made from carbon-intensive fossil fuels.

By enabling infinite recycling cycles, Samsara Eco aims to eliminate the reliance on virgin plastics and minimize textile waste. Paul Riley, CEO of Samsara Eco, emphasizes the urgent need to reuse materials already in circulation to protect the planet. Additionally, Samsara Eco plans to collaborate with customers in the textile and automotive sectors. They will trial the new enzymes at their innovation campus in Jerrabomberra, New South Wales, which is set to open by mid-2025.

INVISTA Drives Post-Consumer and Post-Industrial Recycling Solutions

INVISTA is approaching nylon recycling with practical, patent-backed solutions. Their first patent covers recycling high relative viscosity nylon 66 through mechanical methods. This innovation enables broader use of mechanically recycled feedstocks that were previously unsuitable for critical downstream applications. Additionally, INVISTA has filed a patent for an ammonolysis process that breaks down post-consumer nylon waste into virgin-equivalent monomers. Although early in development, this chemical recycling technology shows promise for improving economic viability and expanding the use of recycled nylon. These initiatives align with INVISTA’s Stewardship Framework, which aims to optimize resource management and reduce environmental footprints. INVISTA is also actively collaborating with startups and technology developers. These partnerships accelerate innovations and strengthen the long-term sustainability of nylon 66 products.

INVISTA provides polymers for electronics, connectors and electrical equipment, such as fuse boxes, ensuring optimal performance and reliability. Courtesy of INVISTA.

Industry Partnerships Bring Science to Commercial Scale

Technological breakthroughs gain real-world impact when companies collaborate. Samsara Eco and NILIT demonstrate this through their strategic partnership. Together, they are building a recycling facility capable of handling even blended textiles that are difficult to process. The facility, expected to be operational by late 2026, will produce high-quality recycled nylon 66 polymers. Moreover, this initiative will allow textile brands to integrate recycled materials seamlessly into their supply chains. It addresses the massive problem of 92 million tonnes of textile waste added to landfills each year. EosEco technology integrates biophysics, chemistry, biology, and artificial intelligence to create enzymes that break down nylon textiles. Combined with NILIT’s expertise in polymerization and spinning, this partnership will deliver premium recycled yarns. Paul Riley also highlights that creating the first circular pathway for nylon 66 is crucial for reducing planetary harm. Together, they aim to transform discarded clothing and automotive products into valuable resources.

Weaving a Circular Nylon Economy

A strong pattern emerges across these innovations. Each company addresses different recycling challenges and contributes to a broader circular economy. Chemical methods work efficiently for certain material streams. Enzymatic approaches provide precision for complex, colored, and blended textiles. On the other hand, mechanical recycling remains useful for simpler waste streams. Therefore, this multi-pathway approach creates a resilient foundation for sustainable material recovery. Industries like textiles and automotive will benefit directly from these advancements. At the same time, growing consumer demand and regulatory pressures reinforce the shift toward circular solutions. Together, these trends signal the start of a true materials revolution.

Nylon Recycling as a Catalyst for Industrial Change

In conclusion, nylon’s journey from environmental liability to a circular resource reflects a significant industrial transformation. These innovations demonstrate how creativity, collaboration, and technology can renew even the most challenging materials. Also, for industries often criticized for their environmental impacts, these breakthroughs offer a clear path forward. They provide a blueprint for reducing plastic waste, minimizing fossil fuel reliance, and promoting sustainable manufacturing. Through combined efforts across companies and sectors, nylon is not just recycled, it is reborn as a model for circularity in a more conscious world.