Scaling Up Rubber Recycling Through Mechanochemical Devulcanization

A new large-scale recycling method uses mechanochemical devulcanization to recover and reuse EPDM rubber, enabling circularity without performance loss.

Industries widely use cross-linked ethylene propylene diene monomer (EPDM) rubber in demanding industrial and automotive applications because of its durability, chemical resistance, and heat stability. However, its cross-linked structure prevents melting and reshaping, which makes mechanical recycling extremely difficult.

As a result, most post-consumer EPDM waste ends up in incinerators or landfills, increasing environmental pressure and causing material loss.

You can also read: Recycled Rubber – A Sustainable Alternative to Carbon Black in Tires.

To tackle this issue, Luo et al. devised a practical method for large-scale recycling of cross-linked EPDM using mechanochemical devulcanization. This technique breaks the sulfur bonds within the rubber matrix, enabling reprocessing of the material without compromising its essential properties.

Mechanochemical Devulcanization: A Scalable Solution

The method applies high-shear force milling to induce chain scission and break sulfur cross-links in the EPDM rubber network. As a result, the cross-linked rubber transitions into a form that can be mixed and reshaped like a thermoplastic material. Moreover, the process uses no chemical solvents and operates at an industrial scale, making it environmentally cleaner and cost-effective. The devulcanized cross-linked ethylene propylene diene monomer (EPDM) is blended with virgin rubber, creating new compounds without requiring major equipment or formulation changes.

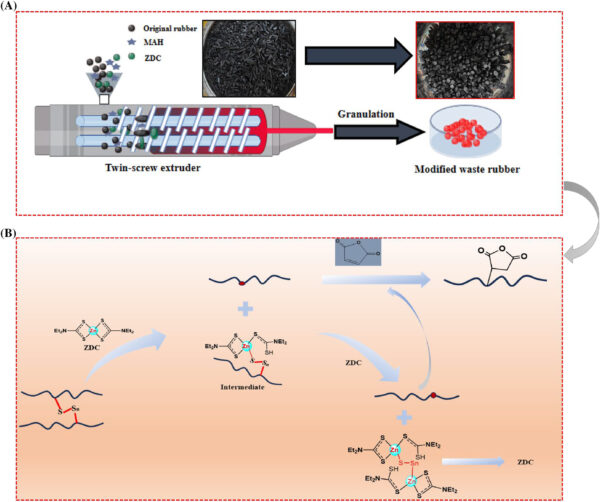

(A) Twin-screw extruder regeneration and modification process, (B) regeneration mechanism of devulcanization-grafting in the extrusion process. Courtesy of Large-scale recycling of waste cross-linked ethylene propylene diene monomer enabled by devulcanization-grafting strategy.

Performance of Recycled Rubber Blends

The research evaluated how different levels of recycled EPDM—up to 50 weight percent—affected material properties in final compounds. The blends showed good processability, indicating that recycled EPDM can be reintegrated without disrupting manufacturing workflows. Mechanical tests confirmed the recycled blends retained acceptable performance, summarized as follows:

Tensile strength and elongation at break remained within acceptable ranges for standard technical applications.

Compression set values were stable, ensuring suitability for sealing and vibration-damping functions.

Curing behavior showed consistent cross-linking kinetics, confirming compatibility with virgin rubber during vulcanization.

Therefore, the recycled cross-linked ethylene propylene diene monomer (EPDM) demonstrates strong functional compatibility, enabling its use in closed-loop production systems.

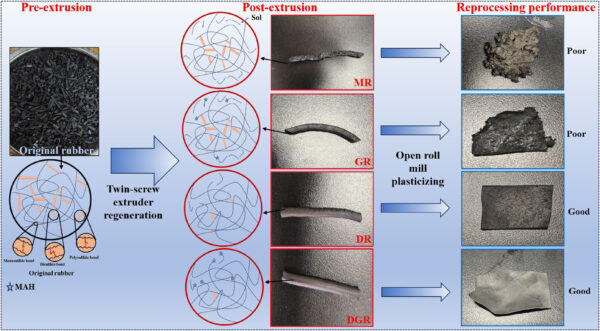

Modification mechanism of different processing methods. DGR, devulcanization-grafting modified waste rubber; DR, devulcanization modified waste rubber; GR, graft modified waste rubber; MAH, maleic anhydride; MR, machine modified waste rubber. Courtesy of Large-scale recycling of waste cross-linked ethylene propylene diene monomer enabled by devulcanization-grafting strategy.

Enabling Circular Use of Cross-Linked Rubbers

This method allows manufacturers to recover value from rubber waste, aligning with circular economy goals in the polymer sector. Because it reduces dependence on virgin raw materials, it contributes to lower resource extraction and reduced energy consumption. Also, unlike chemical devulcanization or pyrolysis, this process avoids hazardous byproducts and maintains polymer structure integrity. For these reasons, it provides a realistic alternative for companies pursuing sustainable practices at an industrial scale.

EPDM Rubber Recycling Outlook

This study demonstrates a viable pathway for recycling cross-linked EPDM rubber using a solvent-free, scalable mechanochemical process. Future work could refine the milling parameters for various EPDM grades and standardize input feedstock characteristics. Moreover, as industries seek ways to reduce environmental impact, this method offers both ecological and economic advantages. Therefore, mechanochemical devulcanization is poised to become a key enabler in sustainable rubber manufacturing and material circularity.