Plasma Treatments Revolutionize Polypropylene Bumper Paintability

Researchers explored how atmospheric pressure plasma (APP) modifies the surface of bumpers to enhance paint adhesion without the need for primers, which is linked to solvent emissions and hazardous waste.

Polypropylene (PP) is preferred for automotive bumpers due to its low cost, light weight, and mechanical properties. However, its low surface energy significantly reduces paint adhesion, forcing manufacturers to rely on primers or chemical treatments. While effective, these conventional methods increase production costs and raise environmental concerns related to solvent emissions and hazardous waste.

You can also read: Nanoparticle Paint Has Potential to Save Weight, Money.

Because the automotive industry seeks cleaner, more efficient solutions, researchers have investigated atmospheric pressure plasma (APP) as a sustainable surface treatment method.

Atmospheric Pressure Plasma as an Eco-Friendly Solution

In this study, researchers explored how APP modifies the surface of PP bumpers to enhance paint adhesion without the need for primers. Unlike chemical pre-treatments, plasma operates at atmospheric pressure and generates active species that physically and chemically modify the material surface. Moreover, plasma systems are relatively easy to integrate into existing production lines, offering potential cost and sustainability benefits. The experimental setup involved varying plasma parameters, such as nozzle distance, treatment speed, and number of passes to determine optimal conditions.

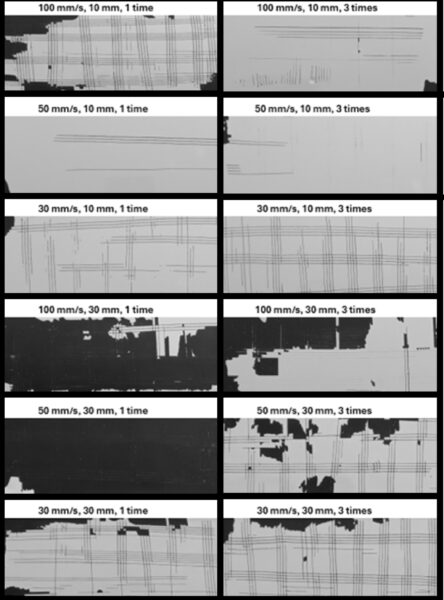

Surface Changes: Roughness vs. Surface Energy

APP treatment caused clear physical and chemical changes to the PP surface. Surface roughness initially increased after plasma exposure, yet researchers observed that roughness alone did not guarantee better paint adhesion. Instead, the key factor was the introduction of oxygen-containing functional groups, which dramatically increased the material’s surface energy. In untreated PP, water contact angles were high, indicating poor wettability. After plasma treatment, contact angles decreased, confirming improved hydrophilicity and higher surface energy. These chemical modifications created a surface better suited to bond with water-based or solvent-based automotive paints.

Contact angle measurements before and after plasma treatment. Courtesy of Investigation of the effects of atmospheric pressure plasma on polypropylene automotive bumper surface and its paintability with and without primer.

Enhanced Paintability Without Primers

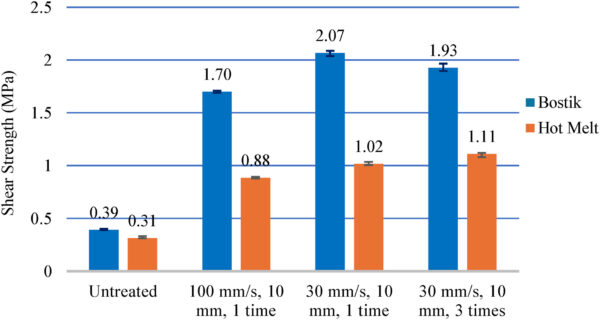

The adhesion strength of painted PP surfaces increased by a factor of three to five following plasma treatment. Interestingly, when surface energy exceeded 45 mN/m, plasma-treated samples passed standard automotive durability tests without the use of primer. These tests included exposure to humidity, acids, water immersion, and mechanical stresses, demonstrating the robustness of plasma-enhanced coatings. Moreover, plasma-treated and primerless samples maintained good adhesion even after accelerated aging, confirming long-term performance viability.

Adhesion strength measurement results. Courtesy of Investigation of the effects of atmospheric pressure plasma on polypropylene automotive bumper surface and its paintability with and without primer.

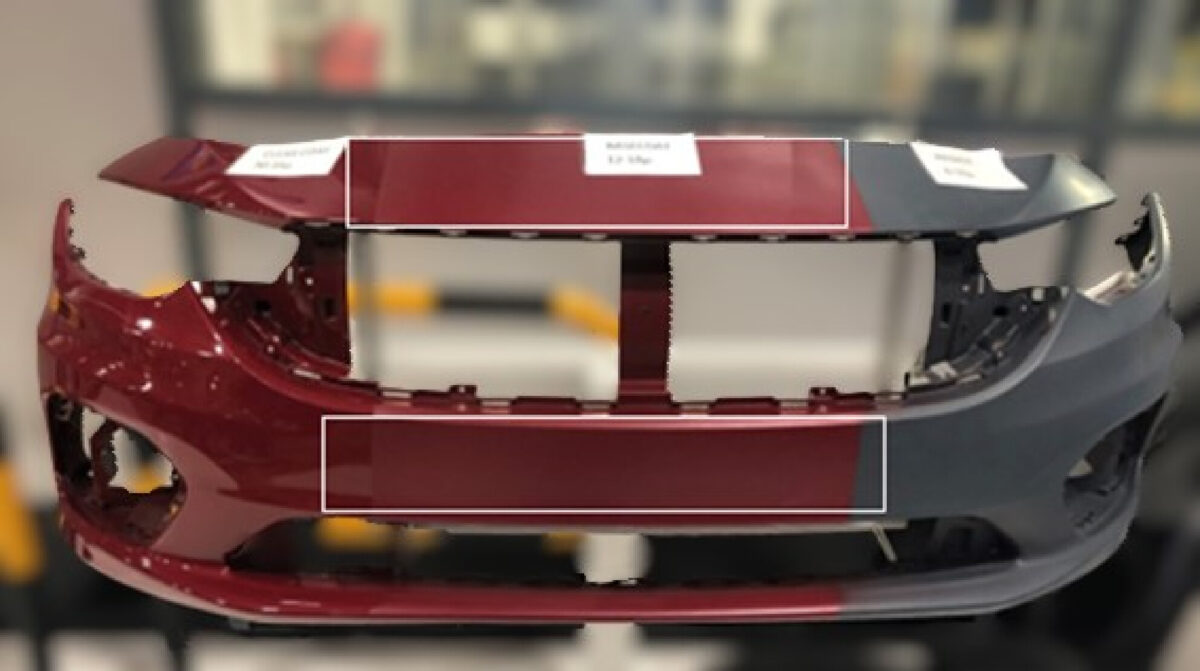

Primerless painted samples of the water resistance tests. Courtesy of Investigation of the effects of atmospheric pressure plasma on polypropylene automotive bumper surface and its paintability with and without primer.

Optimizing the Plasma Treatment

Researchers identified that the best results were achieved with:

10 mm nozzle distance

30 mm/s scan speed

Three passes over the PP surface

These parameters ensured enough plasma exposure to increase surface energy while preventing thermal degradation or surface over-treatment. Thus, by fine-tuning processing conditions, manufacturers can use APP to achieve stable, durable coatings without resorting to traditional primers.

A Path Toward Cleaner Manufacturing

APP treatment offers a sustainable, effective solution for painting polypropylene bumpers without the environmental costs of conventional priming. By focusing on increasing surface energy, rather than simply roughening the surface, plasma enables better adhesion and durability. As the automotive industry pursues greener manufacturing processes, plasma technology positions itself as a key tool for achieving zero-emissions goals while maintaining high-quality standards.