Orange Peel Waste Boosts PBAT Packaging

New research explores how citrus waste can enhance biodegradable films for food applications.

In their recent study, Mohan et al. present a compelling case for reinforcing poly(butylene adipate-co-terephthalate) (PBAT) with orange peel waste powder (OPWP). The study explores how this unmodified agro-waste can improve PBAT’s mechanical and functional performance while accelerating its biodegradability.

You can also read: HDPE vs EPS in Seafood Packaging: A Comparative LCA.

PBAT is already a promising compostable polyester for packaging. However, it lacks active functionality and requires property enhancement for broader use in food applications. The researchers sought to determine whether a natural filler like OPWP could address these gaps, without chemical additives or complex processing.

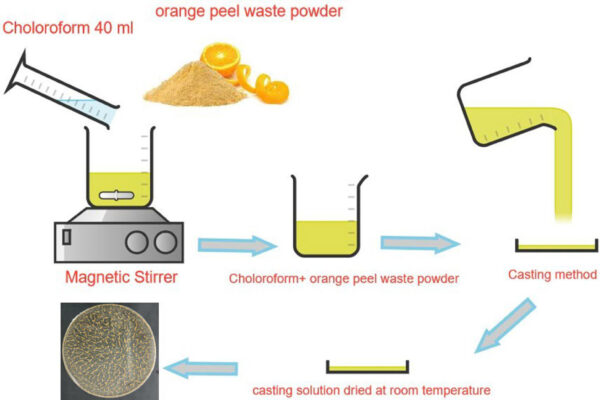

Schematic representation of PBAT/OPWP biofilm preparation. Courtesy of Development and Characterization of Eco-FriendlyPoly(Butylene Adipate-Co-Terephthalate) (PBAT)/OrangePeel Powder Films for Active Packaging Applications.

Reinforcement with Functional Benefits

The team produced films using solution casting, incorporating 5% to 20% orange peel waste powder (OPWP) by weight. Orange peel was selected for its cellulose-rich structure and natural content of phenolic compounds, which are known for their antioxidant and antimicrobial activity.

The results confirmed multiple benefits:

Tensile strength increased by 29% (from 26.9 MPa to 35.7 MPa) at 20% orange peel waste powder (OPWP).

Elongation at break decreased by about 50%, indicating higher stiffness.

UV-B blocking exceeded 99% at 320 nm for films with ≥15% OPWP

Soil degradation reached 76.4% weight loss at 20% OPWP after 21 days, versus 25% for neat PBAT

These gains occurred without compromising barrier performance. Water vapor permeability remained stable, and surface morphology (observed via SEM) showed consistent dispersion of OPWP at lower concentrations. Some particle agglomeration appeared at 20%, but it did not affect the film’s integrity.

Antibacterial and Antioxidant Activity

One key advantage of adding orange peel powder is its natural antimicrobial and antioxidant activity, which suits fresh food packaging. The films reduced microbial growth and slowed oxidation without synthetic additives, thanks to polyphenols and flavonoids in the citrus peel. These compounds stay active in the film and help extend shelf life by preventing spoilage.

Field Test: Bananas Stay Fresher Longer

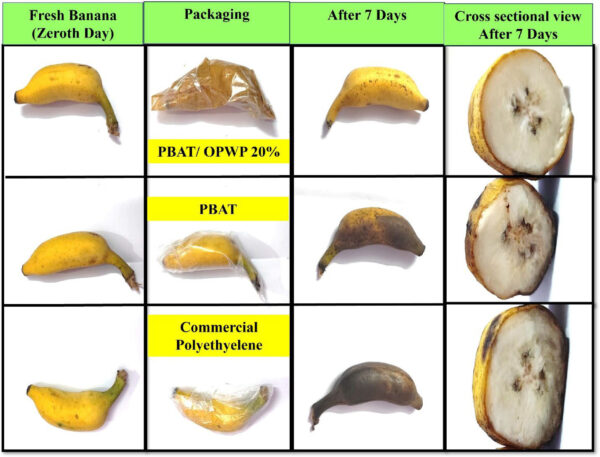

To move beyond laboratory data, the researchers tested the films on a practical application, like banana packaging. Bananas were wrapped in neat PBAT, polyethylene film, and PBAT/OPWP (20%), with an unwrapped sample as control.

After seven days:

Unwrapped and polyethylene-wrapped fruit showed visible spoilage and odor.

PBAT-wrapped bananas showed moderate protection but condensation buildup.

PBAT/OPWP-wrapped fruit retained firmness, color, and a clean appearance, with no detectable odor.

As a result, this trial demonstrated the film’s real-world utility, where its moisture balance, UV-blocking, and antimicrobial properties combined to delay spoilage effectively.

The visual appearance of bananas stored in the open air and in various plastic bags for 7 days. Courtesy of Development and Characterization of Eco-FriendlyPoly(Butylene Adipate-Co-Terephthalate) (PBAT)/OrangePeel Powder Films for Active Packaging Applications.

Biodegradation in Soil: Faster and Cleaner

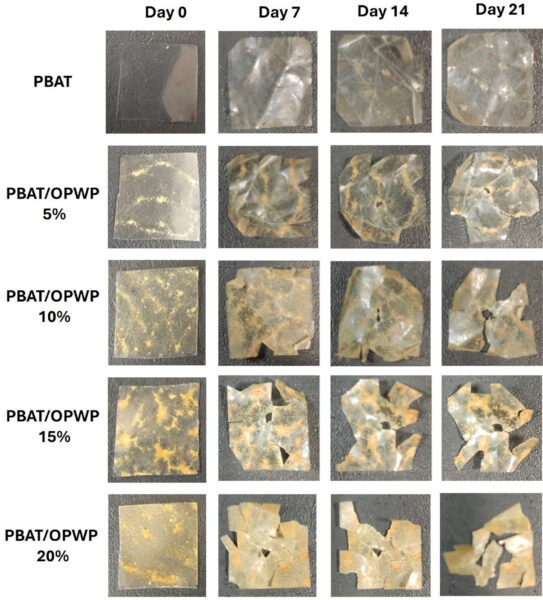

End-of-life performance remains critical for any sustainable packaging solution. In a soil burial test, PBAT/OPWP films showed significantly accelerated degradation. Also, the OPWP component enhanced microbial colonization and hydrolysis due to its hydrophilic, biodegradable nature.

By day 21:

Neat PBAT lost 25% of its mass

PBAT/OPWP 20% lost 76.4%, with no toxic residues observed

This confirms the composite’s suitability for compostable or soil-degradable applications, especially in open or home-composting conditions.

Visual appearance of biodegraded prepared films. Courtesy of Development and Characterization of Eco-FriendlyPoly(Butylene Adipate-Co-Terephthalate) (PBAT)/OrangePeel Powder Films for Active Packaging Applications.

Industry Implications

For experienced professionals in plastics and packaging, this study offers a practical, low-barrier approach to add functional value to an existing biodegradable resin. The formulation uses:

No chemical modifications or compatibilizers

No synthetic additives

A renewable, low-cost filler

Moreover, it aligns with growing demand for active, compostable materials in produce packaging, and supports waste valorization by turning food-processing residues into packaging resources. In conclusion, natural fillers like orange peel powder offer a clear path toward functional, compostable films that align with evolving packaging needs. The next step is to adapt these formulations for industrial-scale processing and confirm their performance in real-world conditions. As demand grows for active, biodegradable solutions, such composites could become key players in the future of sustainable packaging.

I manufacture dried citrus peel products. I have many tons of orange peel powder yearly. I would welcome the opportunity to learn more and provide any material needed for testing and development.

(772) 708-4888