Flame Treatment 4.0: Fire, Science, and Smarter Manufacturing

New digital tools, including fluid dynamics simulations and AI, now allow engineers to optimize flame treatment with unprecedented precision. To understand their impact, let’s explore the latest advancements and their real-world benefits for plastic manufacturers.

Why Flame Treatment Matters?

Flame treatment remains essential for ensuring paint and coatings properly adhere to plastic car parts like bumpers and trim. Specifically, the process uses controlled flames to modify plastic surfaces at a molecular level, creating better bonding sites for coatings. However, finding the perfect balance of flame intensity, speed, and positioning has traditionally required costly trial-and-error testing.

You can also read: Maximizing Injection Molding Simulation

How Researchers Reinvented Flame Treatment

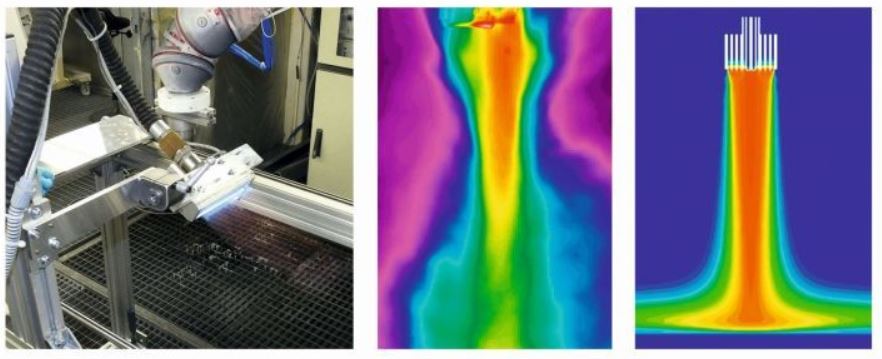

1. Robotic Testing with Precision Controls

First, engineers used robotic arms equipped with industrial burners to treat test plastic panels under varying conditions. During testing, they adjusted:

Burner distance from the surface (3–15 mm)

Traverse speed (100–500 mm/s)

Flame angle (30–90 degrees)

Gas mixture (lean, rich, or balanced)

As a result, this data helped correlate flame settings with surface changes.

2. Advanced Surface Analysis

After treatment, researchers measured results using:

Contact angle tests – To check surface energy and wettability

High-pressure water jets – To simulate real-world coating stress

Infrared thermography – To detect uneven heating risks

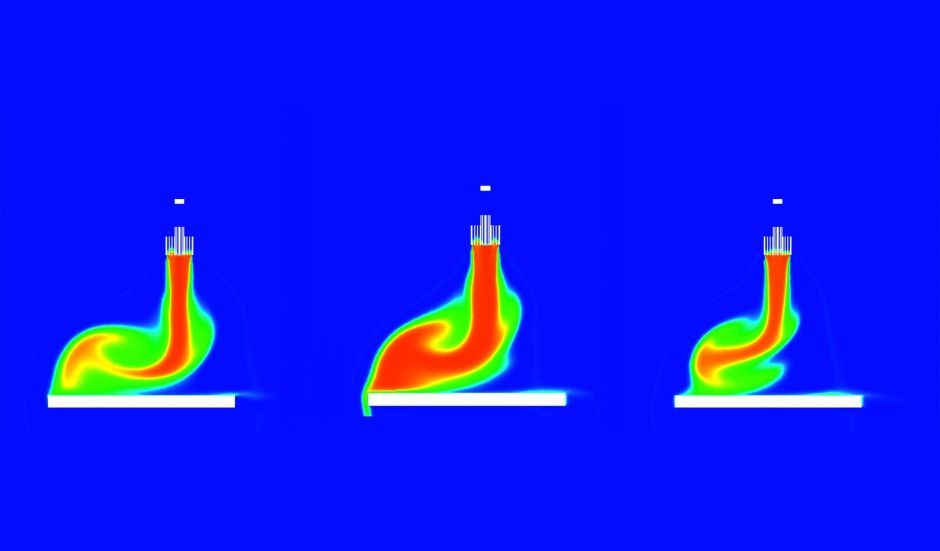

Fluid dynamic simulation results of the dynamic sweeping of the component. Left: stoichiometric gas mixture, center: “rich” mixture and right: “lean” mixture. Courtesy from Fraunhofer IPA

Consequently, these methods provided more profound insights into treatment effectiveness.

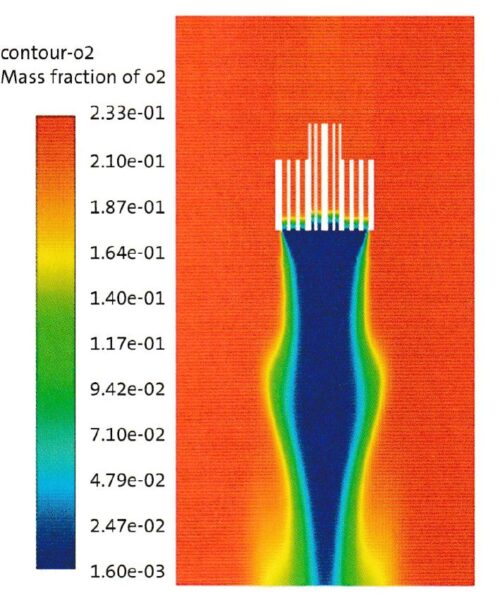

3. Fluid Dynamics Simulations

Next, the team created detailed flame behavior models using ANSYS Fluent software. Notably, the simulations predicted:

Temperature distribution across treated surfaces

Oxygen concentration effects (oxidizing vs. reducing conditions)

How flame shape impacts treatment consistency

Thanks to these models, engineers could optimize flame parameters virtually.

4. AI-Powered Process Optimization

Finally, by feeding experimental and simulation data into machine learning algorithms, researchers developed a predictive model that recommends optimal flame settings for different part geometries. As a result, this eliminates guesswork and speeds up production setup.

Proven Benefits for Manufacturers

Faster Development, Fewer Errors

72% faster parameter tuning for new parts

More consistent adhesion (±5% variance vs. ±15% previously)

Additionally, manufacturers gain efficiency without sacrificing quality.

Cost and Energy Savings

18% less natural gas used per part

8% fewer defects, reducing rework costs

Moreover, these savings add up significantly in large-scale production.

Scalable for Future Needs

Beyond automotive, the same approach works for:

Primer-free coating systems (growing in popularity)

Recycled plastics (requiring precise surface treatment)

Non-automotive applications like electronics and packaging

Thus, the technology is adaptable to evolving industry demands.

Flame oxigen content results from the Fraunhofer IPA Simulation. Courtesy from Fraunhofer IPA

The Future of Flame Treatment

As automakers push for lighter, more sustainable vehicles, optimized flame treatment will play a bigger role in ensuring durable, high-quality finishes. Furthermore, AI and simulation tools make it possible to achieve these results faster and at a lower cost than ever before.

Key Takeaways:

✔ Digital simulations cut development time by 72%

✔ AI models reduce gas use by 18%

✔ More consistent adhesion improves quality

In summary, this means lower costs, less waste, and better-performing coatings for manufacturers—all critical in today’s competitive auto industry.

To read more: Making the activation of plastics more cost-effective and flexible with digital tools – Fraunhofer IPA