Sorting Out the Facts: Bioplastics and Plastic Recycling Can Coexist

Bioplastics often carry a reputation for disrupting recycling systems, yet a recent European Bioplastics study presents a different perspective.

Rethinking the “Contamination” Narrative

Bioplastics often face criticism, yet they can integrate into recycling systems if facilities implement accurate sorting technologies like NIR spectroscopy. Because near-infrared (NIR) systems identify polymers by spectral signature, they can distinguish biodegradables from traditional plastics such as PET, PP, and PE. Many European facilities already use NIR, which allows for efficient sorting of bioplastics and prevents contamination of conventional plastic recycling streams. Recyclers can integrate bioplastics into existing streams when correctly calibrating and updating detection equipment.

You can also read: Enhancing Plastic Sorting Through Deep Learning.

Bioplastics in the Circular Economy

Although composting is often the intended end-of-life route, many biodegradable plastics enter conventional waste streams without specialized collection systems. To prevent these from being incinerated, material recycling offers an alternative recovery pathway within broader circular economy frameworks. Because bioplastics are renewable and degradable, their inclusion in recycling strategies supports long-term goals for resource efficiency and climate resilience. Hence, when sorted correctly, biodegradable plastics not only reduce landfill but also contribute to reducing fossil-based plastic demand over time.

Sorting Technology Makes the Difference

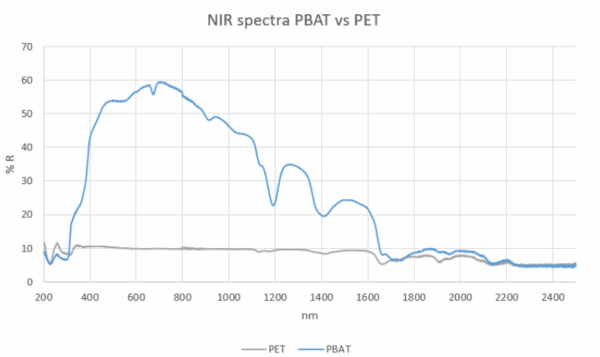

Since poor sorting creates contamination, successfully integrating bioplastics depends on efficient, polymer-specific separation technologies at recovery facilities. Because polymers like PLA, PBAT, and PHA have distinct NIR spectra, existing systems can identify and separate them reliably and rapidly.

Overlayed NIR spectra for PBAT and PET, showing very distinct differences. Courtesy of Biodegradables and material recycling—a paradox?

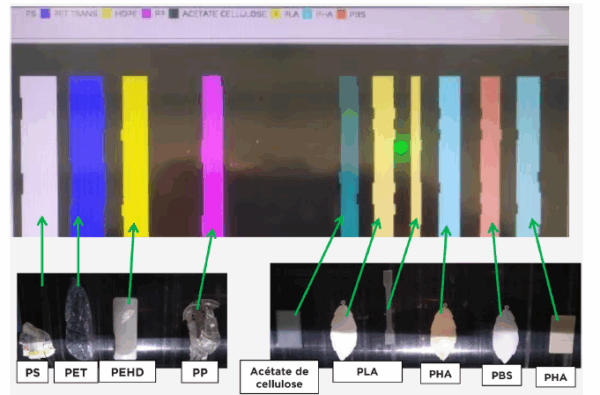

Trials by TOMRA and SEALIVE have shown that NIR technology correctly sorts biodegradable plastics with error rates below contamination thresholds. Moreover, dynamic sorting tests revealed that PLA did not interfere with PET streams, proving compatibility when detection settings are correctly configured.

The NIR screen display (color signals above) shows biodegradable plastics (samples below) as distinct from each other and from other polymers during the SEALIVE tests in 2020. Courtesy of Biodegradables and material recycling—a paradox?

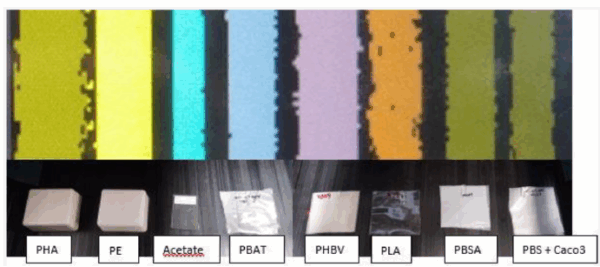

The NIR screen display (colour signals above) is showing biodegradable plastics, including films

(samples below), as distinct from each other and from other polymers, during the SEALIVE tests, September 2022.Courtesy of Biodegradables and material recycling—a paradox?

Case Studies from Italy and Beyond

Italy leads the EU in compostable packaging use, and its recycling data confirms bioplastic contamination rates remain exceptionally low post-sorting. For instance, sorted plastic bales contained less than 1% biodegradable content, far below levels that impact mechanical recyclate quality. Similarly, Dutch and Spanish facilities showed consistent sorting accuracy using NIR, even when processing both rigid and flexible bioplastics simultaneously. Therefore, existing infrastructure across Europe demonstrates that bioplastics can be sorted without compromising fossil-plastic recovery streams or product quality.

Policy and Industry Implications

To improve sorting reliability, the European Bioplastics Association recommends recyclers update NIR systems with spectra for PLA, PBAT, and PHAs. Manufacturers of sorting equipment should also standardize these reference spectra, ensuring uniform detection capability across EU material recovery facilities. These measures align with the EU’s Packaging and Packaging Waste Regulation (PPWR), which mandates high-quality recycling and reduced incineration rates. Consequently, policy and technology must evolve together, ensuring recycling systems adapt to the rising share of bioplastics on the market.

No Paradox, Just Progress

Critics have long warned that bioplastics disrupt recycling, but evidence proves compatibility when detection technology is properly deployed and maintained. As sorting systems evolve and bioplastic volumes increase, the potential for contamination decreases rather than grows, provided oversight remains strong. Hence, the question is not whether bioplastics belong in recycling streams, but whether infrastructure can keep pace with material innovation. Ultimately, bioplastics represent a viable and sustainable solution—as long as sorting efficiency and technological precision remain a clear priority.