Rethinking Energy Averages in LCA for Injection Molding

Generic life cycle data hides the actual energy impact of injection molding and limits the ability to identify real opportunities for efficiency.

Energy consumption in injection molding varies far more than most life cycle assessments (LCAs) can capture. Despite growing pressure to quantify environmental impacts across the plastics value chain, current LCA practices still depend on generalized inventory data, missing the technical aspects of the molding process.

Recent studies confirm that injection molding energy demand varies significantly based on multiple technical factors. These include machine type, polymer rheology, mold design, and screw geometry. Databases like Ecoinvent use average values to simplify comparisons. However, this approach often leads to inaccurate energy consumption estimates for real production scenarios.

You can also read: Two Ways to Reduce Energy Consumption in Injection Molding.

Energy Demand Is Process-Dependent

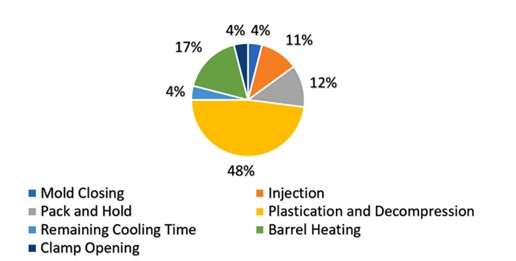

Injection molding involves multiple stages: plastication, packing, holding, cooling, and ejection. Each stage has different energy demands. Plastication, including screw rotation, barrel heating, and decompression, represents the most significant energy share. This stage accounts for up to 48% of total energy consumption in typical operations. Plastication phase is susceptible to four key factors: screw design, backpressure, barrel insulation, and polymer crystallinity.

Different screw types, such as barrier, metering, and multi-flight geometries exhibit distinct shear profiles and melting efficiencies. Likewise, heater bands (mica, ceramic, or cast types) influence heat transfer rates and thermal losses. These parameters can result in measurable differences in energy intensity even for the same molded part.

Cycle time optimization, particularly during cooling, further contributes to consumption variability. Molds equipped with conformal cooling channels or advanced thermal control systems reduce pump loads. Generic LCA datasets often ignore these differences.

Relative energy consumption of stages in injection molding. Courtesy of Energy consumption variability in life cycle assessments of injection molding processes: A critical review and future outlooks.

Equipment Design Drives Performance

Injection molding machines differ fundamentally in how they generate motion and pressure. Hydraulic presses provide high clamp force but incur substantial standby losses due to continuous oil circulation and preheating requirements. In contrast, all-electric machines deliver power on demand and consume energy only during active motion. Hybrid machines mix drive systems to balance force and efficiency.

LCAs that treat all injection presses as energy-equivalent fail to reflect these structural distinctions. Energy consumption profiles vary not only by machine type but also by actuation system configuration, servo motor efficiency, and control logic. Similarly, the type of mold runner system, cold vs. hot, has a direct impact on scrap generation and thermal load. Cold runners increase material waste, while hot runners increase sustained energy use through electrically heated manifolds.

Incompatibilities in Modeling Approach

Conventional LCA relies on either database values or singular case studies to estimate energy use. Surveys or reports typically supply these inputs by averaging consumption data from unrelated applications. This approach overlooks key dependencies such as shot size, barrel utilization, and cycle time.

Empirical studies have shown strong correlations between specific energy consumption and throughput efficiency. When the melt volume closely matches barrel capacity, thermal utilization improves, reducing specific energy consumption per kilogram. These relationships remain absent in LCA frameworks.

Simulation-based energy models provide a more accurate alternative. By using Moldflow® simulations along with heat transfer and mechanical models, they can estimate energy demand in finer detail. Recent studies have also tested machine learning models trained on processing data to predict energy use under different conditions. However, these methods remain underutilized in environmental assessments.

Technical Requirements for Better LCAs

Accurate environmental assessments need to capture how energy behaves in different molding scenarios. Fixed-input models fail to account for the high variability in processes like injection molding. Instead of treating energy as a fixed value, we should model it as a function of process variables. To achieve this, LCA tools must integrate process-aware modeling approaches.

One method involves coupling injection molding simulators with LCA software to allow dynamic data generation based on geometry, polymer type, and machine specifications. Another option is to develop modular LCI datasets categorized by machine type, clamping force, actuator system, and mold configuration. These datasets can provide upper and lower bounds for expected energy use under defined conditions.

Process monitoring systems offer a path to real-time energy data collection. Many facilities already equipped with Industry 4.0 platforms can extract cycle-stage consumption data directly from machine controllers. This data can support application-specific LCAs with significantly greater accuracy than current averages.

The Future: Data Integration

Adoption of refined modeling approaches depends on better alignment between LCA methodology and process engineering. Life cycle analysts require inputs formatted for impact calculation, while plastics engineers operate with machine parameters and thermal loads. Translating between these domains demands structured collaboration and shared reference frameworks.

Energy models based on process physics and real measurements can make LCA results more useful. To support this shift, the industry needs to standardize how it collects data, define common molding scenarios, and agree on clear parameter definitions across different fields.