Reducing Computational Costs in Warpage Prediction

Researchers seek to better understand warpage in injection molding using Multi-Fidelity Neural Networks (MFNN).

Unintentional warpage of plastic parts is a common issue during injection molding. To prevent it, manufacturers must narrow down the cause of this phenomenon and alter the injection molding parameters accordingly. Traditional methods for detecting defects and quickly optimizing parameters do not always meet manufacturers’ needs. A multi-fidelity solution may prove a viable—and less costly—solution for manufacturers and engineers.

You can also read: Essential Tips for Designing Injection Molded Parts.

Understanding Warpage

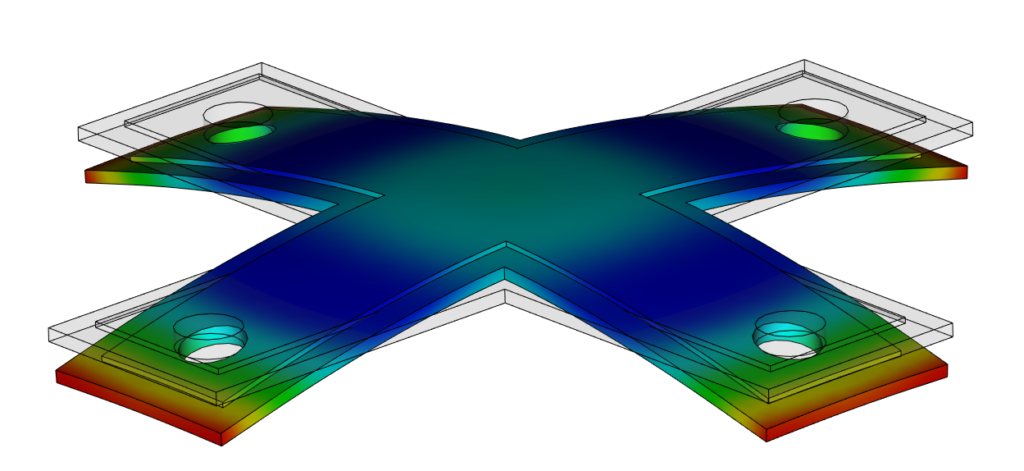

Many factors, such as material properties or part design, can lead to warpage. The process parameters during injection molding can also be a contributing factor. For example, variations in part thickness or shear stress during filling could be why plastic parts have warped.

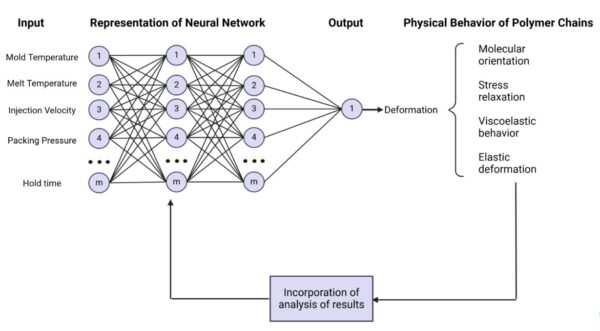

By integrating a neural network into the inspection process, manufacturers and engineers can discover—and address—links between these factors. Neural networks can understand the relationship between inputs such as mold temperature and packing pressure in real time. Nevertheless, relying on high-fidelity data can lead to high computational costs.

Neural networks can learn from and interpret data to improve the injection molding process. Courtesy of Multi-Fidelity Neural Network Approach for Warpage Prediction and Optimization in Injection Molding, presented at SPE’s ANTEC® 2025.

A Multi-Fidelity Solution

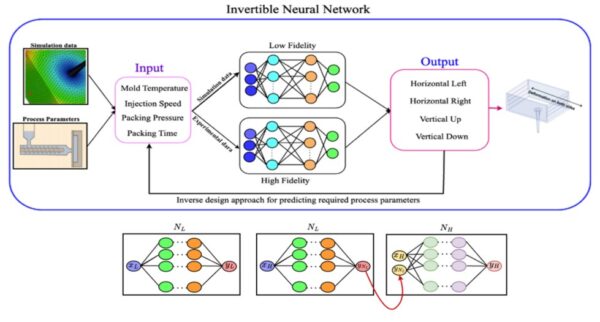

Researchers at the University of Delaware used a multi-fidelity approach to creating a neural network for analyzing warping. That is, a framework that combines both:

- Low-fidelity data, derived from simulations

- High-fidelity data, collected experimentally

Instead of relying on high-fidelity data only, a multi-fidelity neural network cuts computational costs by integrating these low-fidelity data. To collect experimental data, researchers painted the edges of molded parts, then photographed them. From these images, researchers calculated the amount of warpage in mm, as well as whether it was concave or convex. Researchers also collected data from in-mold sensors.

You can also read: Intro to Plastics: Solving Jetting in Injection Molding.

Using Moldex3D, a simulation generated low-fidelity data using the same parameters as the experiment. Using both data sources, researchers created an invertible neural network. This type of neural network can reconstruct input data from output data, and thus, predict required process parameters.

The invertible neural network uses both simulation data and experimental processing parameters to provide higher accuracy for warpage predictions. Courtesy of Multi-Fidelity Neural Network Approach for Warpage Prediction and Optimization in Injection Molding, presented at SPE’s ANTEC® 2025.

Data visualization from the MFNN clearly showed the relationship between mold wall temperature and thickness. A thicker wall led to slower cooling and thus, more time for stress relaxation. Thinner walls promoted rapid cooling, with frozen molecular orientation and higher residual stress. Upon testing, the MFNN demonstrated an improvement in prediction accuracy.

This approach, using these combined data sources, shows promise for more effective neural networks to support manufacturers using injection molding. High-fidelity data requires less data and produces higher quality results than low-fidelity data. This comes at the expense of much higher requirements for computational power. A multi-fidelity approach allows for a middle ground between the two—an exciting advancement for intelligent manufacturing.