Inside Materials – Polystyrene

Polystyrene (PS) is a thermoplastic that industries widely recognize for its lightweight nature, durability, and excellent protective properties.

German pharmacist Eduard Simon discovered polystyrene (PS) in 1839. However, limited knowledge of its properties and potential applications prevented companies from commercializing it for nearly a century. In 1937, researchers at Dow Chemical developed a purified styrene monomer and initiated a pilot polymerization process to produce PS. The effort proved successful, and by 1938, the company had launched large-scale production and marketing of the polymer. Since then, PS has stood out as a versatile, lightweight, insulating, and cost-effective material.

You can also read: Inside Materials – Polycarbonate.

Exploring Polystyrene

PS is a synthetic resin that manufacturers produce by polymerizing styrene. In its simplest form, it appears as a transparent, stiff, and brittle polymer that industries commonly use in various applications. Its nonpolar nature makes it ideal for thermal and electrical insulation and for resisting moisture. Additionally, PS offers good resistance to many chemicals, including acids and bases.

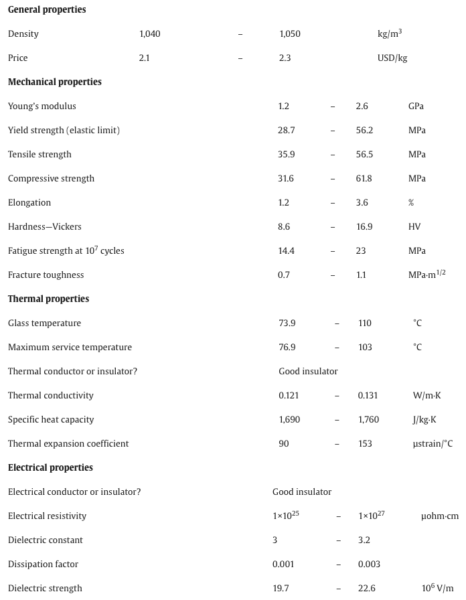

General, mechanical, thermal, and electrical properties of polystyrene. Courtesy of Polystyrene- ScienceDirect.

Thanks to its low shrinkage rate and strong insulating properties, processors can easily shape this material through injection molding. Manufacturers frequently choose PS as one of the top plastics for injection-molded parts. However, they must consider certain limitations during processing, such as brittleness, a low melt flow index, and a narrow processing temperature range.

Types and Applications

Currently, three common types of PS dominate the market:

- Crystalline PS or General Purpose PS (GPPS): This standard, clear, and rigid form of PS features excellent transparency. This makes it ideal for food packaging, cosmetic containers, disposable tableware, and laboratory equipment.

- High-Impact PS (HIPS): This modified version of PS includes butadiene rubber units in its structure. Its high mechanical strength, improved ductility, and opacity make it suitable for automotive parts, yogurt containers, toys, and household appliances.

- Expanded PS Foam (EPS): As the best-known type of PS, EPS stands out for its lightweight, rigid structure and outstanding insulation properties. Industries use it widely in construction, protective packaging, sports helmets, and the transportation of vaccines and clinical samples.

Sustainability: Recycling

When assessing the environmental impact of polystyrene, it is essential to recognize that recycling plays a critical role. Today, industries recycle all types of PS, creating a valuable opportunity to support a circular economy.

However, PS recycling poses several challenges. It involves high costs, generates low product value, and depends on limited recycling infrastructure. Inadequate logistics, weak policies, and the absence of standardized recycling practices in current waste management systems cause these issues. Governments and companies must improve impurity removal, strengthen market resilience, and collaborate with other fields—such as logistics, environmental science, and engineering—to enhance PS recycling systems.

Despite the work that remains, organizations like the Polystyrene Recycling Alliance (PSRA) actively address these challenges. They promote PS recycling and advance the circularity of PS products across North America.

You can also read: Colombia’s Push for Polystyrene Recycling at ANTEC® 2025

Market Outlook and Industry Leaders

Finally, experts foresee polystyrene to maintain a strong position in the market. They valued the global PS market at USD 5.98 billion in 2024, with projections estimating it will reach USD 7.63 billion by 2030. Leading companies such as BASF SE, Synthos S.A., and DuPont de Nemours Inc. are anticipated to drive this growth.