Enzymatic Polymer Degradation: How Does It Work?

There is growing interest in enzymatic degradation as an alternative to biodegradation, though its full potential is not yet certain.

The plastics industry urgently needs sustainable solutions to tackle polymer waste, and enzymatic degradation is rising to the challenge. This innovative approach goes beyond traditional recycling methods by using nature’s recyclers and microbial enzymes to break down plastics efficiently at room temperature.

You can also read: Carbios Broadens Enzyme Recycling Technology

The Biochemical Mechanics of Plastic Degradation

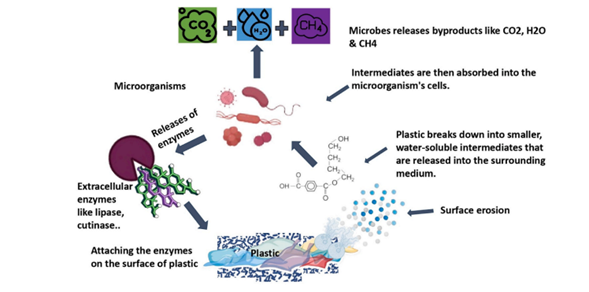

Enzymes break down plastic polymers through two fundamental biochemical processes. The first pathway involves hydrolysis. In this process, specialized enzymes called hydrolases target and cleave the ester bonds in polyesters such as PET and PU. These enzymes work by strategically inserting water molecules into the polymer’s molecular structure, breaking the long chains into smaller fragments until only the original monomer units remain.

The second pathway breaks down hydrocarbon-based plastics like PE and PP through oxidation. Oxidoreductase enzymes, such as laccases and peroxidases, start the process by oxidizing the strong carbon-carbon bonds in the polymer backbone. This reaction weakens the molecular structure, creating reactive sites. These sites then enable further breakdown by microbes or other enzymes.

In summary, nature uses two precise mechanisms to break down polymers. The hydrolytic pathway works well for ester-containing plastics, while the oxidative pathway breaks down tougher hydrocarbon-based plastics found in packaging and consumer goods.

Mechanism of action of enzymes in biodegradation of polymers. Courtesy of Comprehensive review on enzymatic polymer degradation: A sustainable solution for plastics.

These enzymatic processes do not occur in isolation. On the contrary, specialized microorganisms power these processes, developing unique capabilities to digest plastics through natural evolution. Recent studies highlight the impressive specificity of these enzymes. For example, PETase from Ideonella sakaiensis has a unique binding pocket that fits PET’s aromatic terephthalate units. Meanwhile, Pseudozyma antarctica cutinase is highly effective against aliphatic polyesters like PBS. While this enables targeted degradation, it also requires enzyme cocktails to address mixed plastic waste streams.

Microbial Factories: Nature’s Plastic Recyclers

A variety of microorganisms have evolved to use plastics as carbon sources. Bacterial strains like Pseudomonas and Bacillus colonize polymer surfaces, forming biofilms that concentrate degradative enzymes at the plastic-microbe interface. Fungal species such as Aspergillus tubingensis use hyphal networks to penetrate deeper into polymer matrices, with some strains breaking down up to 28% of HDPE films in just 60 days.

Scientists have made a breakthrough discovery about how ocean bacteria break down plastics. The marine bacterium Rhodococcus ruber has shown remarkable ability to degrade polyethylene. Researchers found that when exposed to simulated wave motion, this bacterium breaks down plastic up to 50% faster than in still conditions.

In parallel, studies of wax worms (Galleria mellonella) have revealed their gut bacteria naturally produce plastic-digesting esterase enzymes. These symbiotic relationships in nature are inspiring scientists to develop new bio-based solutions for plastic waste management.

From Lab to Industry: Scaling Enzymatic Solutions

Translating laboratory successes into industrial applications involves addressing three key factors: reaction kinetics, enzyme stability, and economic viability. Current research focuses on:

- Immobilization Techniques

Scientists boost enzyme performance by anchoring them to advanced materials. For example, PETase enzymes fixed onto graphene oxide sheets or magnetic nanoparticles become more heat-resistant and reusable.

- Process Intensification

By applying enzymatic action under controlled conditions, researchers reduce PET degradation time from months to days. For example, the Carbios demonstration plant in France processes two tons of PET waste daily using engineered enzymes. The process operates under low temperatures at atmospheric pressure, which enhances enzymatic efficiency.

- Downstream Processing

Membrane filtration systems are being adapted to separate degradation products like TPA and EG, achieving purities above 99%. These high-purity products are then suitable for repolymerization.

Barriers and Breakthroughs

Enzymatic degradation shows promise but still faces key challenges. First, enzymes struggle to break down crystalline regions in semi-crystalline polymers. Researchers are tackling this by developing “pre-digestion” treatments using ionic liquids. Second, accumulating monomers can inhibit enzyme activity (called end-product inhibition). Scientists are overcoming this limitation by implementing systems that remove products during the reaction.

Most critically, enzyme production costs remain high. However, emerging solid-state fermentation methods using agricultural byproducts could reduce costs by up to tenfold. Additionally, directed evolution techniques have created mutant enzymes with up to thirty times greater activity, as shown by the University of Portsmouth’s engineered PETase variant.

The Road Ahead

In the next decade, enzymatic processes will enhance mechanical recycling rather than replace it. Hybrid systems are already in use, where extrusion first breaks down material size followed by enzymatic depolymerization. To support this shift, engineers should redesign materials by incorporating hydrolysable linkages during polymerization or using additives that do not interfere with enzymes.

As regulatory pressures increase, especially around single-use plastics, enzymatic degradation provides a strong path to circularity. With global enzyme markets expected to reach $8.7 billion by 2026, economic incentives are aligning with environmental needs. For plastics professionals looking ahead, now is the time to embrace this transformative technology.