The UAE to Host the World’s Largest PLA Production Facility

Emirates Biotech and Sulzer are joining forces to build the UAE’s world’s largest PLA production facility. This initiative aligns with global environmental goals and the UAE’s Green Agenda 2030.

The upcoming PLA plant will be the largest in the world, producing 75,000 metric tons annually. Located strategically in Abu Dhabi’s KEZAD Free Zone, the facility will span 135,000 square meters. Construction will begin before 2026, with commercial operations starting in early 2025.

By leveraging its strategic location, the facility will serve growing markets in the Middle East, Africa, and beyond, solidifying the UAE’s position as a key player in the global bioplastics sector.

Facility Capabilities: A Benchmark in Bioplastic Production

Emirates Biotech is set to establish a groundbreaking Polylactic Acid (PLA) production facility that will redefine global standards in bioplastic manufacturing. The plant will feature a scalable and efficient design constructed in two phases. Each phase will deliver an annual production capacity of 80,000 tonnes, culminating in a total output of 160,000 tonnes annually. This makes it the largest PLA production facility in the world, underscoring its pivotal role in advancing the bioplastics industry.

Environmental Impact and Global Reach

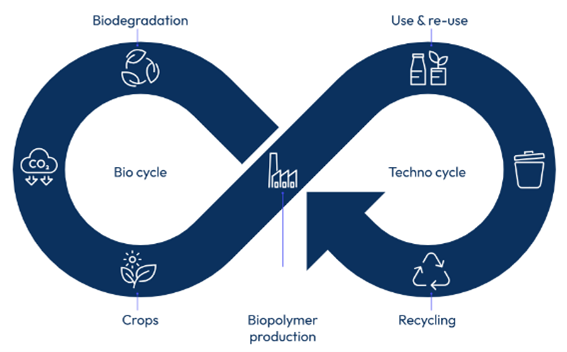

The facility’s massive production capacity translates into significant environmental benefits. Once operational, it will produce enough PLA to replace approximately 3.2 billion plastic bottles annually. The plant will switch to plant-based and biodegradable bioplastics, reducing carbon dioxide emissions by over 300,000 tonnes per year and significantly contributing to global efforts to combat climate change and plastic pollution.

Transforming CO2 into eco-friendly biodegradable polymers. Taken from Emirates Biotech.

Pioneering Green Technology Through Strategic Collaboration

Sulzer’s PLA technology is widely recognized for its efficiency and environmental benefits, offering a sustainable alternative to fossil fuel-based plastics. Moreover, the collaboration between Emirates Biotech and Sulzer highlights a shared dedication to advancing the bioplastics industry and driving eco-friendly innovations.

The planned large-scale PLA production facility by Emirates Biotech in the United Arab Emirates. Courtesy of Emirates Biotech.

Furthermore, the plant’s design emphasizes sustainability at every level. By using renewable plant-based feedstock as its raw material, the facility achieves a low-carbon manufacturing process, reinforcing its commitment to environmentally responsible practices. Additionally, by producing PLA—a versatile and biodegradable alternative to traditional plastics—the facility supports diverse applications, such as packaging and disposable items. These efforts help reduce dependence on single-use plastics and contribute to a more sustainable future.

I never thought of the UAE as a center of local / sustainable agricultural production.. I believe there must be a ‘backstory” for a global petroleum powerhouse to move large-scale resource toward building a massive facility that will be (at least partially) dependent on bioproducts THAT THEY WILL NEED TO IMPORT. My first thought after reading the above is “sounds too good to be true”… My second thought is that logistics should not be ignored when building ‘green stories’ (and they are so often…). If this organization will be trucking in ~50,000 tons of agricultural product to ‘feed their new beast’…this ‘green story’ just got a little brown…