Biodegradable Polyester Fiber for Fashion Solutions

INTIMITI Australia CELYS biodegradable fiber offers a groundbreaking and eco-friendly alternative to traditional problematic polyester in the fashion industry.

Annually, approximately half a million tonnes of microfibers enter the oceans from washing clothes. This phenomenon is increasing with rising textile production and consumption. To mitigate this, researchers consider two strategies: developing biodegradable materials and enhancing wastewater treatment to capture microfibers. The professional team at INTIMITI Australia focuses on the first strategy, which is to create a biodegradable polyester material, CELYS. This fiber outperforms conventional PET fibers, enabling its use as a sustainable alternative in textile production.

You can also read: The Fashion Industry Needs an Alternative to Recycled PET

Biodegradation Properties

Under industrial conditions, CELYS can break down at 95.4% into harmless byproducts such as water, carbon dioxide, and biomass in just 179 days. Incorporating easily hydrolyzable linkages into the polymer backbones during polyester polymerization contributes to this remarkable capability.

Due to its biodegradable properties, CELYS meets the ASTM D6400 standard in the United States and the EN13432 standard in European countries. As a result, it has also earned certifications from DIN CERTCO and BPI.

Advantages of CELYS Over PET

- Cotton Touch: CELYS polyester boasts a unique molecular structure that imparts a cottony touch, making it softer than standard PET fibers.

- Low Pilling: CELYS polyester’s distinctive chemical makeup results in lower tensile strength than regular PET fibers, which provides a natural solution to concerns about pilling.

- Hydrophilicity: With hydrophilic groups in its fiber structure, CELYS absorbs water rapidly. It exhibits a moisture regain approximately four times that of standard PET fibers.

- Low Temp Dye: Unlike traditional PET fibers, CELYS fibers can be dyed at 100°C using cationic dyes. Medium and low-energy dispersed dyes can also dye them.

- Natural Wicking & Breathability: CELYS polyester fibers contain numerous naturally formed channels that swiftly wick moisture away from the skin, promoting excellent breathability.

- Quick Dry: CELYS maintains excellent quick-dry performance typical of polyester fibers, further enhanced by its numerous natural channels, facilitating faster vaporization.

Additive Based ‘Biodegradable’ Polyester vs. CELYS

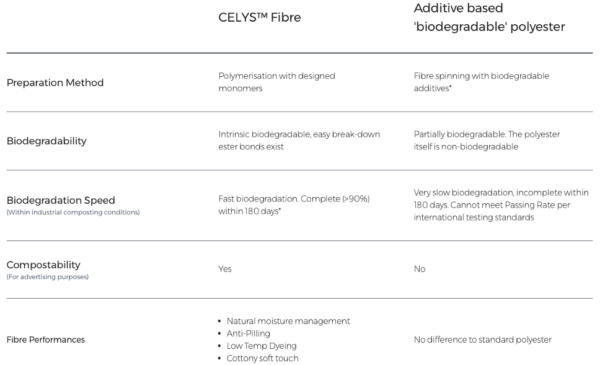

While CELYS presents advantages over conventional PET, it also outperforms additive-based ‘biodegradable’ polyester in several aspects. Unlike the latter, which merely alters the microphysical structures of PET, potentially leading to microfiber or microplastic issues. CELYS actively transforms the chemical structure, offering more comprehensive environmental benefits.

Comparison chart between CELYS fiber and additive-based ‘biodegradable’ polyester. Courtesy of CELYS.

Future Directions of CELYS Sustainability

To ensure that no textiles or waste products end up in landfills at the end of their life cycle, INTIMITI has a recycling technology for CELYS fiber. Soon, as volumes accumulate, they will invite brand customers to join this recycling project.

The project allows the collection and recycling of used CELYS textile products. This process retrieves valuable monomers, which researchers then use to reproduce CELYS™ fibers.

CELYS represents a significant step toward a circular economy, where materials are reused, recycled, or returned to their natural environment.

For inquiries and further details about the CELYS proposal, click here. Explore their certification program for fabrics featuring CELYS fiber.