Understanding Impact Damage on Single-Ply TPO Membrane Roofing

Did you know that during a hailstorm, your home’s roof is at risk of damage? The extent and type of damage depend mainly on the roofing material.

Lehigh University researchers, in collaboration with GAF Materials LLC, conducted a study about the impact damage in fully adhered commercial roofing systems. This research involved a combination of experimental drop tests and finite element models. The results identified the primary damage mechanisms affecting single-ply TPO (Thermoplastic Polyolefin) membrane roofing.

You can also read: Pressure Points: Thermoforming Awards Highlight Processing and Materials

Fully-adhered TPO Single Ply Structure

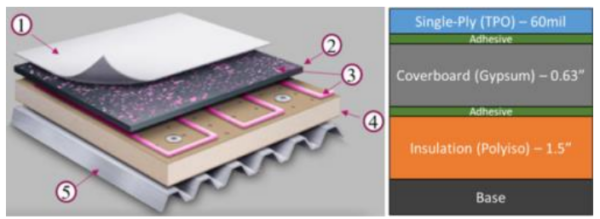

A single-ply TPO (Thermoplastic Polyolefin) membrane has five layers. From top to bottom: TPO membrane, faced gypsum cover-board, faced polyiso insulation layer, and roofing substrate.

Schematic of a fully-adhered TPO single-ply roofing system. (1) TPO membrane; (2) Cover-board; (3) Adhesive; (4) Polyiso insulation; (5) Roofing substrate. Courtesy of Assessment of Impact Damage in Fully Adhered Commercial Roofing Systems, Antec 2024.

Researchers utilized a drop tower to conduct impact tests, employing cylindrical steel darts and steel balls. The rectangular samples consisted of three main layers: a TPO membrane, a gypsum coverboard, and a polyiso insulation layer. Each reinforced with additional layers for strength. Scientists tested two configurations: fully adhered with adhesives and non-adhered.

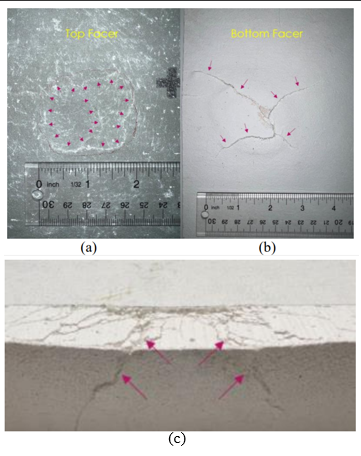

Also, researchers employed various drop heights to replicate impact energies similar to those of hailstones. Initially, at lower drop heights, they did not detect any cracks on any outside surfaces within the layered components. However, as the drop height increased, cracks began to emerge, particularly on the bottom face of the cover board. At the highest drop height, cracks also developed on the top face of the cover board. Furthermore, researchers observed internal damage within the cover board, including cone-shaped cracks within the gypsum core.

Interestingly, despite these findings, the TPO membrane remained undamaged throughout the impact tests. Notably, cracks on the top face of the polyiso insulation exhibited similar shapes to those on the bottom face of the cover-board.

(a), (b) Cracks on the cover board at h=3.34m. (c) Cracks in the gypsum core and on the bottom face of coverboard at h=3.34m. Courtesy of Assessment of Impact Damage in Fully Adhered Commercial Roofing Systems, Antec 2024.

Identifying Stress Hotspots Through FEA

Engineers conducted a series of finite element simulations using ANSYS Mechanical modeling to better understand the cause of the damage. Employing quasi-static simulations, they assumed that the kinetic energy from the indenter was completely converted to elastic strain energy. These simulations provided researchers with insights into the distribution of strain energy among the components. They aided in understanding the observed damage mechanism.

The circular shape of the cracks on the top face of the coverboard correlates with the shear stress distribution. Similarly, cracks on the bottom face of the cover-board and the top facer of the polyiso insulation exhibited comparable patterns. They initiated at the impact center and developed radial cracks. The location with the highest principal stresses on these facers was directly underneath the impact center. This indicates that cracks likely originated there and developed radially. Notably, cracks on these facers occurred due to tension, unlike cracks on the top face of the cover board.

Furthermore, impact tests conducted at low energies revealed that the gypsum layer could develop an internal cone-shaped crack from as low as 10.6 J of impact energy.

Appreciations for Future Design

Researchers have gained valuable insights into the key damage mechanisms affecting single-ply TPO membrane roofing. The extensive studies underscore the significant vulnerability of the gypsum cover board during hailstorms. Simulation results closely align with experimental observations, indicating that cone-shaped cracking in the gypsum cover-board is the dominant failure mechanism. This cracking is strongly associated with the local maximum shear stresses in the multiaxial compressed region beneath the impactor. Such insights are crucial for enhancing the durability and resilience of roofing systems against hailstorm damage. Hence, contributing to improved building safety and structural integrity.

This is a great and informative read on the impact damage to single-ply TPO membrane roofing. I appreciate how you broke down the various types of damage and the testing methods used to evaluate the material’s durability. It’s interesting to see the role that puncture resistance and tear strength play in the overall performance of TPO membranes, especially in harsh weather conditions. Your explanation of how membrane thickness and reinforcement layers influence impact resistance is especially insightful.

I’m curious about the long-term performance of TPO membranes in areas prone to extreme heat, such as desert climates. Have there been any recent advancements in TPO formulations or installation techniques to further improve their durability in these environments?