Ink Effects on LDPE Recycling: A Comprehensive Study

Low-density polyethylene (LDPE) is a staple in flexible plastic packaging, but ink contaminants pose challenges in mechanical recycling.

You can also read Advancements in LDPE Synthesis and Recycling.

Recycling is vital for achieving a circular economy, yet flexible plastic products, including LDPE packaging, pose significant recycling challenges. With limited recycling rates and complex pathways, enhancing recycling efficiency is essential for sustainability. This study delves into the effects of ink components on LDPE recyclates, focusing on thermal behavior and recycling impacts.

Understanding Ink Formulation and Composition

LDPE printing ink contains various compounds, including solvents, pigments, binders, and additives. These components are crucial in ink performance and properties, affecting LDPE recyclability and final product quality.

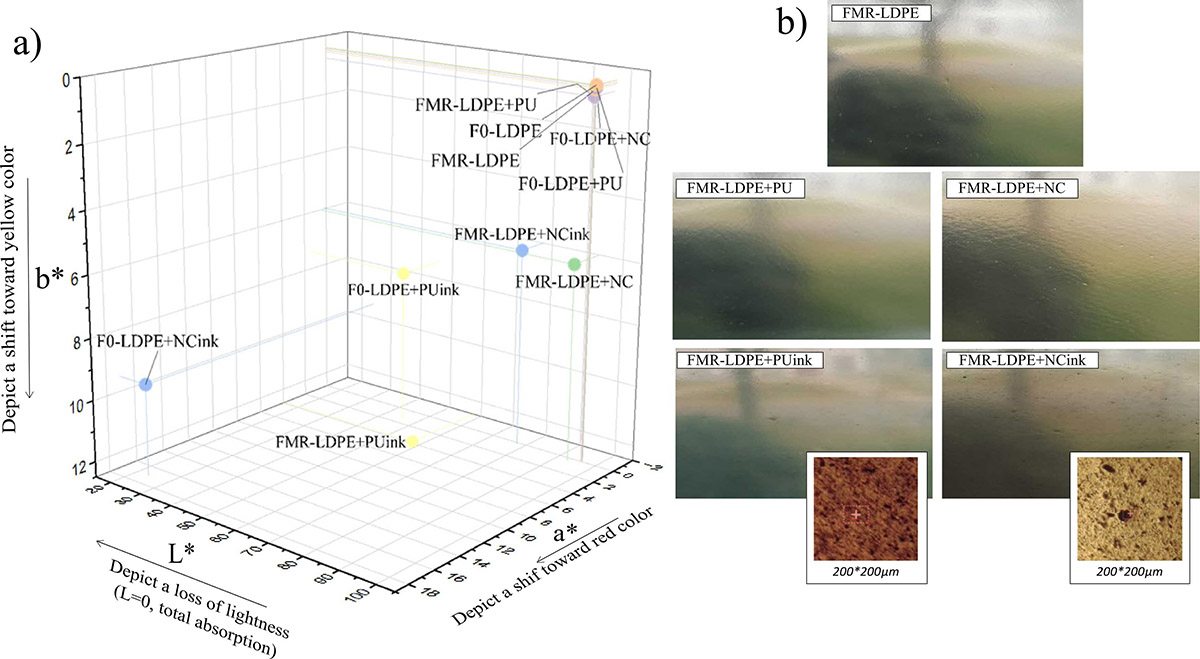

The study aims to evaluate the impact of ink formulation on LDPE recycling, focusing on binders (polyurethane and nitrocellulose) and pigments (yellow, red, and blue). LDPE films were printed, recycled, and analyzed for mechanical, physicochemical, and aesthetic properties.

Findings: Ink Effects on Recycled LDPE Properties

Nitrocellulose binder degradation during reprocessing leads to film discoloration and odorous compound emission. Pigments disperse within polyurethane binder droplets, affecting film properties like impact resistance and strain at break. Ink components emit volatile compounds during reprocessing, further compromising recyclate quality.

Implications for LDPE Recycling and Circular Economy

Contaminants from inks, whether undergoing degradation or persisting in recycled material, impact recyclate quality, posing challenges for circularity. Addressing ink-related contamination is crucial for improving LDPE recycling efficiency and reducing environmental impacts.

The study underscores concerns about ink contaminants in recycled LDPE, emphasizing the need for intensified recycling efforts. Understanding ink degradation profiles and their effects on recyclate quality is essential for advancing sustainability in the plastic industry.

Driving Efforts Towards Sustainable LDPE Recycling

By unraveling the complexities of ink impacts on LDPE recycling, this study provides valuable insights for designing more recyclable plastic packaging. Further research is needed to fully understand ink degradation and its implications for circularity and environmental sustainability.

Read more in the Journal of Hazardous Materials.