How to Measure Headspace in Packaging

Reducing the excess headspace in flexible packaging allows companies to diminish the demand for virgin plastics and decrease the volume of plastic introduced into the market.

Unnecessary headspace is essentially “packaged air,” so minimizing it can yield direct savings on packaging materials, as well as reduce logistical and transportation emissions and costs.

You can also read: Golden Design Rules: Benefits of Reducing Packaging Headspace

The Importance of Headspace

Headspace is crucial for manufacturers to protect their products and maintain freshness. However, this space must conform to certain global standards. For instance, excessive headspace that misleads consumers about the product quantity can lead to package rejection. Notably, experts consider 30% the maximum allowable headspace.

Measuring Headspace

There are several methods for measuring headspace, which vary depending on the product’s nature and the packaging’s geometry. For a complete guide to headspace measurement methodology, click here.

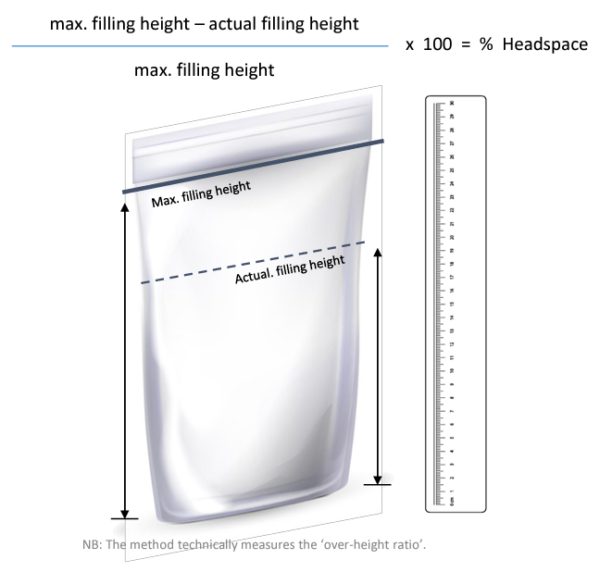

Linear Method

This common approach is not highly accurate but remains straightforward to apply.

Syringe Brim-full Method

This technique calculates the void percentage, which is not identical to headspace but can be slightly higher. It is predominantly used for liquids.

Displaced Volume Method

This method is highly accurate but complex to execute. To measure headspace using this method:

- Fill the packaging with the product at the planned sale weight.

- Pierce a small hole at the top of the package and gently squeeze out the air.

- Seal the hole with tape to prevent water entry.

- Submerge the package fully in a container of water and record the volume of water displaced (measure A).

- Refill the package to its maximum capacity, repeat the air expulsion and submersion steps, and record the volume of water displaced again (measure B).

This approach provides a detailed understanding of how different levels of product filling affect headspace, offering valuable insights for optimizing packaging design.

Reducing headspace in packaging does more than minimize material usage; it serves as a critical strategy for enhancing sustainability in the packaging industry. Companies decrease their consumption of virgin materials, like plastics from non-renewable resources, by reducing the unused space within packages. This effort not only conserves valuable resources but also reduces the environmental impact of producing and disposing of excess packaging materials.