Vacuum Technology is Key to Firm’s Packaging Approach

Inter Holdings says its patented technology can extend shelf life, save food, and reduce CO2 emissions

A Tokyo-based company has developed and patented what it calls “ultra-high vacuum technology.” It aims to reduce food loss and carbon dioxide emissions while replacing some single-use plastic packaging.

Inter Holdings Inc. says its vacuum containers have a 99.5 percent vacuum rate –– “the highest level on earth” –– which can help to extend the shelf life of foodstuffs up to 10 times longer than with standard storage techniques.

Shin-ku Pouches for Both Solids and Liquids

With a 99.5 percent vacuum rate, Inter Holdings is targeting its containers for both liquid and solid packaging applications.

Its Shin-ku bottles are flexible, standup pouches made at least in part using a combination of transparent metalized PET and LLDPE, according to Sales Manager Casey Okamoto. Its vacuum cap is molded from polypropylene with a polyethylene spout.

“Through our unique vacuum patent technology, we achieve a significant extension of the shelf life of products”–– for solids and liquids, ranging from wine and sake to olive oil, rice, and even blood. This, the firm says, also reduces greenhouse gas emissions and food waste.

Additionally, Inter Holdings says that no specialized equipment is needed (as with conventional vacuum packs). The containers’ simple design means the reusable bottle can be easily cleaned and globally produced.

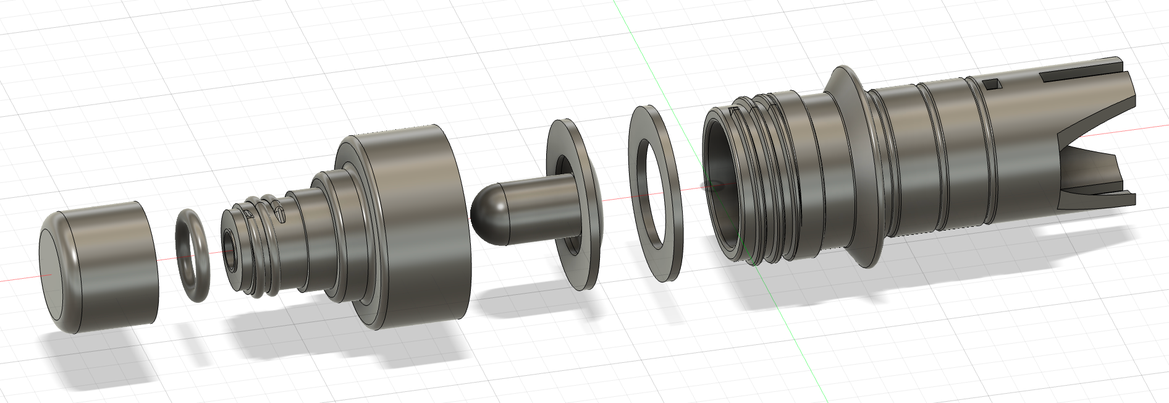

Dome-shaped Check Valve Draws on NASA Technology

The company says the NASA-inspired, dome-shaped check valve is key to its “ultra-high vacuum technology.”

The company, which showcased its wares at the CES 2024 consumer technology show in Las Vegas in January, says the key to realizing such a high vacuum rate is the dome-shaped silicone check valve built into the cap.

It claims that the vacuum check valve, which was created by applying technology once used in rocket development for NASA’s Apollo program, is the world’s only patented technology that maintains a vacuum rate of 99.5 percent. It says that it took a Japanese inventor with knowledge of hydrodynamics 30 years to develop this patent technology.

As for its business model, Inter Holdings currently sells empty vacuum containers, Okamoto said, but it sees the licensing of its technology as the largest future source of income.

Both Large Products and Small

These larger, commercial-scale vacuum servers can be used in hotels and restaurants, the company suggests.

Its range of products includes large commercial vacuum containers, with 100 kg capacity, as well as small, individual pouches. It also markets a device, about half the size of a refrigerator, that the firm calls a vacuum server, which can be used by hotels and restaurants to sample or sell various liquids such as sake, wine, soup stock, and coffee.

Okamoto acknowledges it would be difficult if not impossible to realize its technology without using plastics. He says Inter Holdings aims to be plastic-neutral, or even plastic-negative, going forward. For example, he says, the vacuum sake server will be made out of recycled plastics that the company collects.

Other CES 2024 Stories in Plastics Engineering:

- TERRA is Tackling the Plague of E-waste (March 8, 2024)

- Electric Outboard Motor Brings Zero-emission Propulsion to Water Sports (Feb. 27, 2024)

Leveraging AI to Speed Product Design Simulations (Feb. 23, 2024) - Thermally Conductive Plastic for Cooling Electronics (Feb. 13, 2024)

Turning Origami into Portable Solar Power (Jan. 29, 2024) - Hear! Hear! says a Leading Global Eyewear Maker (Jan. 25, 2024)

- Honda’s Foldable Electric Scooter Earns CES Innovation Award (Jan. 23, 2024)

- Dutch Firm’s Solar City Car Offers Affordable Mobility Option (Jan. 19, 2024)

- Sky’s the Limit for Medical Deliveries by Drone (Jan. 18, 2024)

- Bioengineered House Plant Acts as Natural Air-purification System (Jan. 16, 2024)