Principles Governing 4D Printing

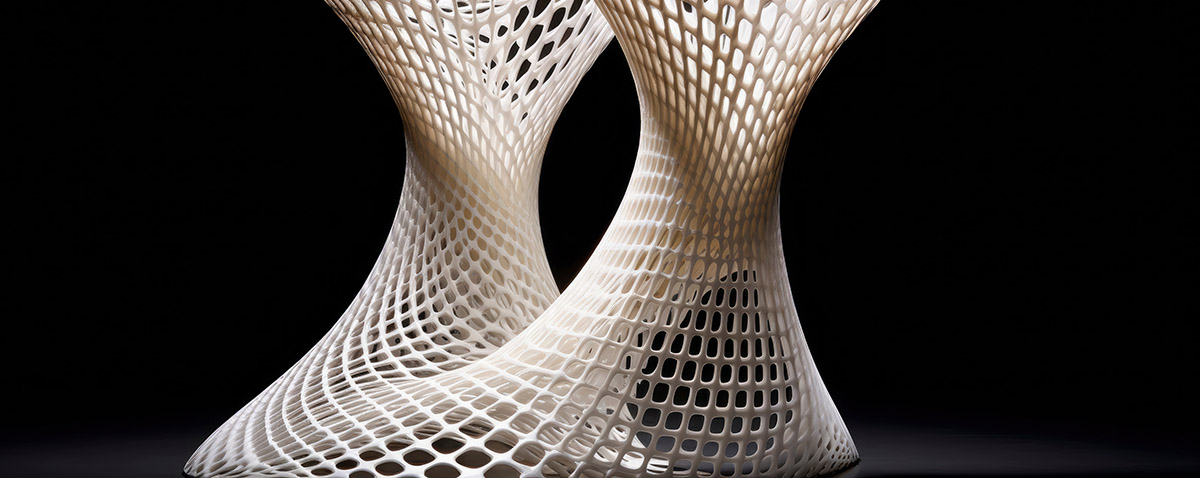

Four-dimensional (4D) printing, an extension of 3D printing, incorporates the dimension of time into the fabrication process, enabling the creation of structures that can change shape in response to external stimuli.

Farhang Momeni and Jun Ni, researchers from the University of Michigan, have articulated three fundamental laws governing the behavior of 4D printed materials, offering a deeper understanding of the mechanics behind these dynamic structures.

You can also read: Dual-Wavelength Light Approach Speeds Vat-Based 3D Printing

First Law: Relative Expansion Between Materials

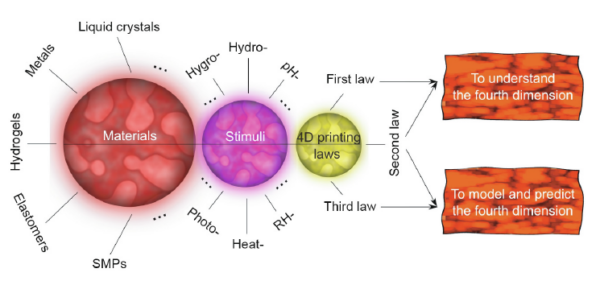

The cornerstone of 4D printing’s magic lies in the “relative expansion” between active and passive materials within the printed structure. This law states that all shape-changing behaviors—such as twisting, bending, and curling—are driven by the differential expansion or contraction of these materials when exposed to stimuli like heat, light, or moisture. The interaction between the smart, responsive materials and the more stable, passive materials creates the conditions for dynamic change.

Second Law: Four Physical Forces Behind Shape-Morphing

The second law delves into the physical forces that drive the relative expansion between materials: mass diffusion, thermal expansion, molecular transformation, and organic growth. Consequently, these forces are responsible for the diverse and complex behaviors observed in 4D-printed objects. For instance, thermal expansion can cause materials to expand or contract with temperature changes, while molecular transformations involve changes at the molecular level that alter the material’s shape without the need for external mechanical force.

Third Law: Time Constants Govern Shape-Morphing Speed

The final law introduced by Momeni and Ni addresses the temporal aspect of 4D printing, focusing on how quickly or slowly the shape-morphing occurs. This law states that two types of time constants—related to the material’s response to stimuli and the inherent properties of the materials themselves—dictate the speed of transformation. These constants help predict how a 4D-printed structure will respond over time, enabling designers to tailor materials and processes for specific applications.

The laws of 4D printing delineate the relationship between structure and time, revolutionizing how we perceive and engineer dynamic systems. Courtesy of Laws of 4D Printing.

Implications and Future Directions

The elucidation of these laws paves the way for advancements in 4D printing technology, with implications across various fields such as medicine, aerospace, and robotics. For example, in healthcare, 4D printed materials could be used to create implants that adapt to the body’s changes over time or drug delivery systems that release medication in response to physiological cues.

Moreover, the integration of smart materials and the precise control offered by 4D printing open new avenues for creating structures that can adapt to their environment, self-assemble, or repair themselves. As the field evolves, understanding and applying these laws will be crucial for pushing the boundaries of what’s possible with 4D printing, ultimately leading to more responsive, efficient, and intelligent systems.

These three laws not only underscore the technical complexity and potential of 4D printing but also highlight the interdisciplinary nature of this emerging field, where material science, engineering, and mathematics converge to create the next generation of smart materials and structures.