Synergists: Boosting Flame Retardant Effectiveness

In the quest for safer and more eco-friendly fire safety solutions, synergists emerge as a solution to enhance non-halogenated FR effectiveness.

As halogenated flame retardants retreat from the market, brand owners seek a replacement. However, developers need to adopt a multimechanistic approach. Since no single material performs as well as halogenated flame retardants, integrating different mechanisms becomes essential to achieve effective, safe, high-performing, and cost-efficient flame retardants.

You can also read: Epoxy-Based Intumescent Flame Retardants in the Oil & Gas Industry

Manufacturers have introduced functional polymers with intumescent and mineral systems to the market, along with synergists. These last are not flame retardants themselves, but they can improve the effectiveness of the multiple FR mechanisms.

How do Mineral-Based Synergists work?

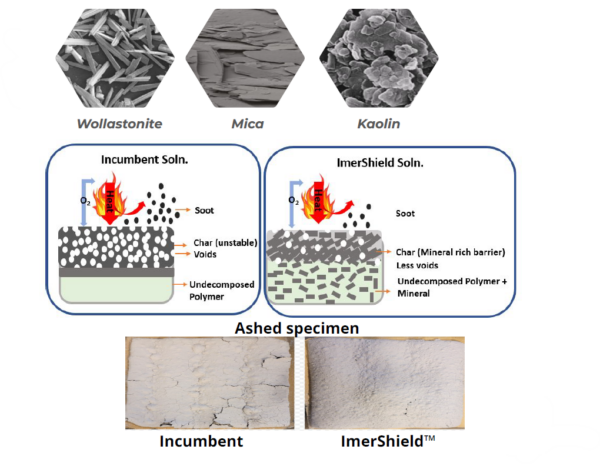

Engineered minerals enhance char formation in materials, providing a dual-function barrier against both heat and oxygen, which are essential for combustion. By integrating these minerals, materials develop a robust, insulating char layer during exposure to fire, significantly slowing down heat transfer and restricting oxygen access to the flammable core. This improved char formation not only boosts the material’s thermal stability but also its resistance to ignition and burning, effectively reducing its overall flammability characteristics. Through this mechanism, engineered minerals offer a sophisticated solution to augment fire safety across various applications, making materials safer and more resilient in fire-prone environments.

Synergistic Mechanism of ImerShield. Courtesy of Imerys.

Synergistically Improved

Imerys, the world leader in mineral-based specialties for the industry has developed ImerShield, a synergist for FRs composites. This new product is a mineral-based FR synergist that is aimed to improve retardancy classifications with lower flame retardant consumption.

Some attributes of this synergist include:

- Improved rheology (spiral mold flow).

- Improves GF debundling.

- Improves surface roughness.

- Improves FR classification at a given loading.

ImerShield for Intumescent Polyamides

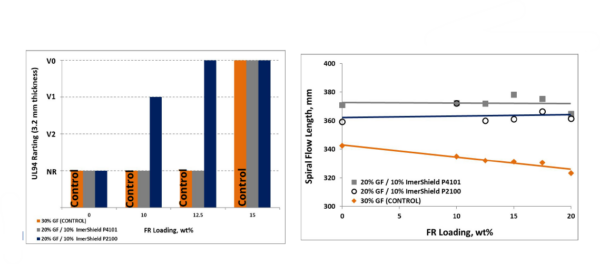

The company evaluated the effect of ImerShield on 30% glass fiber-filled PA6 in an intumescent FR formulation using a phosphinate-based additive. In the case of the synergist, 10% of ImerShield was introduced with 20% of glass fiber. As a result, the ImerShield compound overperformed the control flame retardant with 30% carbon fiber.

Effect of synergist in carbon fiber-filled PA6 flame retardancy. Courtesy of Imerys.

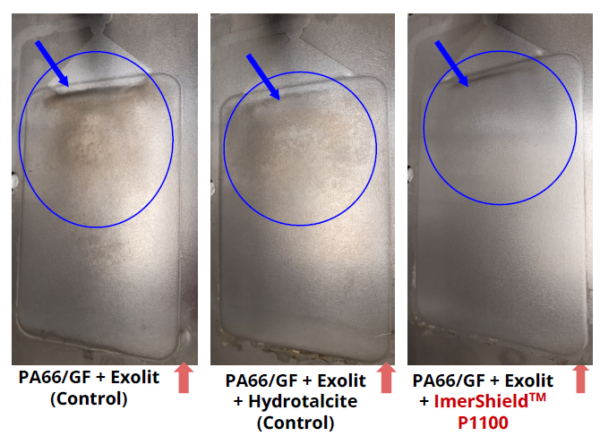

Additionally, ImerShield is tailored to reduce the equipment corrosion/erosion associated with phosphinate-based FR additives and glass fiber.

Corrosion appearance of the removable steel mold inserts after 100 injection molding shots. Courtesy of Imerys.

These synergists amplify the efficiency of non-halogenated flame retardants, adopting a comprehensive strategy to meet rigorous safety and efficacy benchmarks. ImerShield has shown promising results in enhancing material attributes and flame retardant performance, particularly in intumescent Polyamides and Polypropylene. Nevertheless, it is crucial to extend testing to various other polymers to fully ascertain their versatility and effectiveness. Broadening the scope of application will ensure that such innovations provide a universally applicable, sustainable solution in fire safety, fostering a new era in flame retardant technology.