Bio-based Solvents for Polyimide Synthesis in Space Applications

The arduous space environment conditions require polymers with superior properties.

Nowadays, one of the harshest challenges is the development of polymeric materials for the aerospace industry. In particular, in space, engineers encounter challenging conditions. High levels of radiation (UV and solar radiation), fluctuating extreme temperatures, vacuum conditions, and microgravity characterize space.

You can also read: Embracing Sustainability With Bio-based Flame Retardants

High-Performance Polyimides

After multiple research endeavors, scientists have found polyimides (PIs) to be the ideal material for this application. Specifically, polyimide membranes are functional in solar propulsion sails and large deployable and inflatable structures.

PIs have high thermal stability, mechanical strength, and UV and solar radiation resistance. The presence of aromatic and benzene rings and -CF3 functional groups gives PIs these properties.

Sustainability Problems of PIs Synthesis

Scientists commonly synthesize aromatic PIs with highly toxic solvents. These have a significant environmental impact and adverse effects on human health. As a result, in December 2023, the Sapienza University of Rome and the Italian Space Agency presented research about an eco-friendly synthesis of PIs. The researchers aim to replace conventional solvents without compromising the properties of PIs. The new solvents used in the research are Cyrene and DMI.

Bio-based solvents play a crucial role in reducing CO2 emissions, as well as water pollution during the processing of polyimides.

Eco-friendly Synthesis Process

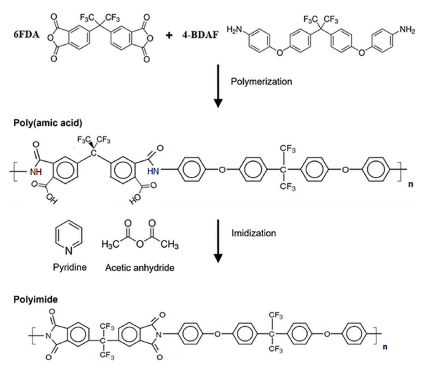

The synthesis of PIs with trifluoromethyl (-CF3) functional groups involves two stages. The first stage is polymerization of PAA, where the reaction between the monomers 6FDA and 4-BDAF occurs in each solvent. Scientists carry out this process in an argon atmosphere. The second step of the synthesis is imidization. The idea is to chemically imidize PAA with acetic anhydride and pyridine. At the end of this stage, researchers obtained PI powders after applying other subprocesses. Engineers subsequently utilize them to fabricate PI membranes. This process also requires bio-based solvents.

PFAs Concern

As mentioned in the previous paragraph, the PIs from the research contain trifluoromethyl. This characteristic may raise concerns regarding the use of PFAs and existing regulations. However, it is relevant to consider ASD-Eurospace’s statement regarding universal PFAS restrictions.

In summary, the proposal to restrict PFAs would be disproportionate and unmanageable for the space niche sector. Investigations indicate some relevant cases in which PFAS chemistry is the only viable solution for space missions.

For polyamides, the –CF3 groups prevent chain packing among the polymer chains.

Properties of the Eco-Synthesized Polyimides Membranes

Finally, researchers found that PIs synthesized with DMI solvent have properties equal to those of PIs with conventional solvents (DMAc). These results represent significant advancements for greener solvents in the aerospace industry.

Although PFAs are of significant use in the aerospace industry, research on bio-based high-performance PIs may be the next step forward for the industry.