Antimicrobial Nanofilm Pioneering Food Preservation

In the Alabama A&M University (AAMU) Food Engineering Lab, a groundbreaking initiative is underway, poised to revolutionize food preservation and packaging technology.

Harnessing Hemp for Antimicrobial Solutions

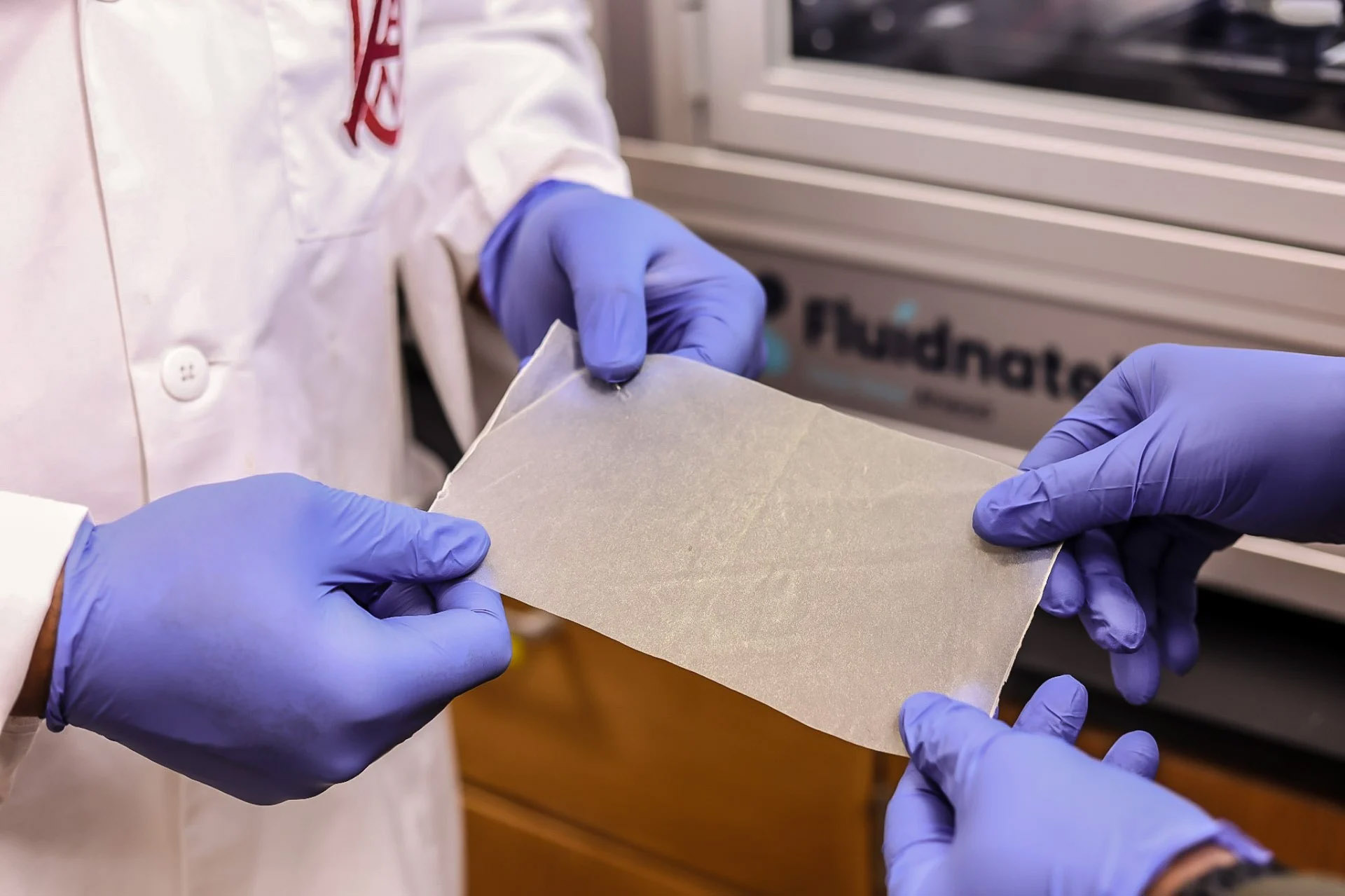

Leveraging hemp cultivated at AAMU’s Winfred Thomas Agricultural Research Station, students are spearheading the development of an antimicrobial nanofilm. Unlike conventional plastic wrap, this innovative material possesses the unique ability to eradicate or inhibit the growth of hazardous bacteria prevalent in food, including Salmonella and Listeria.

Professor Lamin M. Kassama, a leading authority in Food Engineering/Processing at AAMU, elucidates the concept of antimicrobial packaging as an active solution. By imbuing materials with antimicrobial agents, the packaging becomes active, releasing compounds upon interaction with the package material, thereby mitigating microbial proliferation.

Cutting-edge Fabrication Techniques

Students utilize the Fluidnatek LE-50, an advanced electrospinning and electrospraying system from Nanoscience Instruments Inc., to craft the active film. Through a meticulous process involving the extraction of phytochemicals from hemp powder dispersed in ethanol, coupled with polymer infusion, the film is electrospun into existence.

Cutting-edge film packaging, developed using nanotechnology and natural hemp, could change the way food is protected.

The LE-50 system facilitates the creation of a nano-scale antimicrobial film wrap. Aaron Dudley, a Ph.D. candidate, underscores the significance of encapsulating materials at the nano scale, enabling precise drug delivery and bolstering antimicrobial efficacy.

“We grind the hemp into a powder and disperse it in ethanol in order to extract the phytochemicals,” said Aaron Dudley. “Every phytochemical that’s ethanol soluble will basically leave the plant material and go into the solution of the ethanol. We take that and mix it with a polymer that helps us to electrospin.”

Promising Results in Food Safety

In rigorous testing conducted on fresh chicken, the antimicrobial film demonstrates remarkable efficacy in inhibiting the growth of Salmonella enterica and Listeria monocytogenes under refrigerated conditions, thus fortifying food safety standards.

Eco-friendly and Futuristic Outlook

Professor Kassama highlights the biodegradability of the active film, derived from hemp—a natural source. With ongoing research, the active packaging film holds promise for scaling up to pilot and commercial production, heralding a new era in food preservation technology.

While the technology remains in its nascent stage, Dudley envisions its potential expansion into commercial bandwidth within the next three to five years, ushering in a new wave of applications spanning packaging, clothing materials, and beyond.