AI-Driven Carbon Fiber

The case study from Citrine on the AI-driven development of additives for the carbon fiber manufacturing process outperformed conventional approaches by 4x in its ability to pinpoint viable candidates. This illustrates the transformative impact AI and machine learning (ML) have on materials science.

The Citrine and KCARBON Collaboration

Collaborating with KCARBON, a South Korean agency dedicated to advancing carbon fiber technology, Citrine, a pioneering company that has developed an AI platform specifically for the development of materials and chemicals, embarked on a project to develop a new additive formula to enhance carbon fiber manufacturing. Starting with no initial data, this endeavor achieved remarkable results within five months, demonstrating AI’s power to accelerate and refine the research and development process.

You can also read: Closing the Carbon Fiber Loop

The additive formulation must meet five high-priority criteria (other properties are also important and monitored):

- Meet the dispersion standard.

- Meet processing requirements.

- Improve a physical property.

- Not cause defects.

- Improve a mechanical property.

AI-Driven Methodology and Results

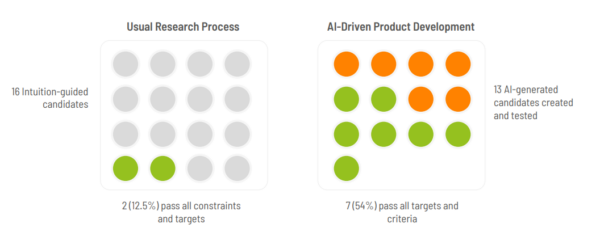

In traditional research methodologies, identifying promising additive formulas is time-consuming and less efficient. However, Citrine’s AI model outperformed these conventional approaches by 4x in its ability to pinpoint viable candidates. Furthermore, after just three iterations of Sequential Learning, the AI model suggested a recipe that matched the effectiveness of existing commercial products, a significant achievement given the project’s nascent stage.

This project highlighted several key advantages of integrating AI and ML into materials science. First, it showcased the ability to rapidly generate actionable insights and high-potential candidates with minimal starting data. Second, the approach significantly reduced the need for extensive experimental trials, traditionally a resource-intensive aspect of materials development. Lastly, the case exemplified how AI-driven methodologies could guide future research directions, offering a scalable, efficient path toward innovation.

Also, the project produced valuable insights for the customer. They quickly learned that the current ingredient inventory was insufficient to simultaneously achieve all the performance targets, which focused their efforts on which new ingredients to source.

Such AI-driven projects are not just about accelerating the pace of development; they also represent a shift towards more data-driven, predictive approaches in materials science. BBy leveraging machine learning models, researchers can explore vast compositional and formulation spaces quickly and accurately. This opens new possibilities for discovery and optimization previously deemed impractical or too costly.

“AI-based material development is efficient and easy to use. It helped us go beyond intuitive recipes,” said Dr. Moonheui Hahn, Project Manager at KCARBON.

Usual Research Process vs AI-Driven Product Development. Courtesy of Citrine Informatics.

The Future of AI in Materials Science

The success of this project with KCARBON serves as a compelling case for the broader adoption of AI and ML technologies in materials science and beyond. These tools significantly advance science, enabling breakthroughs with unprecedented efficiency and precision in overcoming complex challenges.

For further insights into the capabilities and applications of AI in materials science development, exploring resources and case studies provided by Citrine can be an excellent starting point. Their work exemplifies the cutting-edge intersection of AI technology and material innovation, marking a new era of possibilities in the field.