Next-Gen Rotomolding: Robotics Enhancing Innovation

Robotic rotational molding is an advanced technology that enables the development of unique geometries, tight tolerances to achieve part-to-part repeatability, and less waste than conventional plastic molding.

The traditional rotational molding process allows the production of plastic parts of various sizes, shapes, and textures. However, despite its simplicity and advantages, the process remained stagnant for over 50 years due to a lack of significant technological innovations, hindering the competitive growth of rotational molding in the industry.

History Of Rotational Molding Technical Innovations

Since 2002, some companies have been developing methods to automate Rotational Molding. The first attempt was made in Italy by the company Perisco, with the Leonardo machine, which was capable of automatically filling the material, closing the mold, heating, and cooling the cycle, and demolding. Later, this same company developed an improved version known as SMART in 2011, which uses electricity to heat the mold and has a more compact size. Finally, AMS in Belgium implemented a robotic arm that provides greater flexibility and control of the mold.

Robotic Rotational Molding Advantages

The implementation of the robotic arm in the rotational molding process is part of what is known as Robotic Rotational Molding, which has several advantages. Firstly, this type of technology eliminates the use of the hot oven and consequently implements new programmable electric heating and cooling systems that not only improve the quality of the final product but also have a favorable environmental impact (approximately, 90% less of emissions). Likewise, with the absence of extreme temperatures in the environment, temperature and pressure sensors can be installed to control the different zones of the product and thus have greater control over the material and wall thickness. Finally, the use of the robotic arm provides movement in all 6 axes, unlike the 2 axes of the conventional process.

Case Study: Gemstar

Gemstar is an American company that has solved various case studies using Robotic Rotational Molding. One of them corresponds to the development of a specialized fuel tank for a groundskeeping equipment manufacturer.

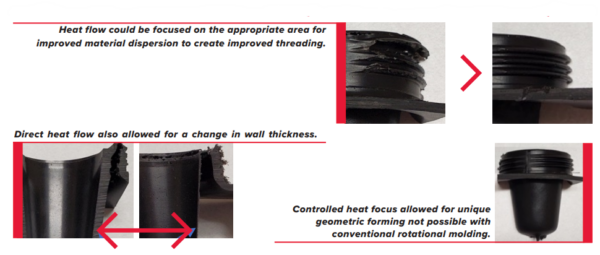

Controlled heat flow for Gemstar Case Study inner funnel and external thread. Courtesy of Gemstar.

The project faced two constraints: meeting EPA requirements and ensuring adherence to quality standards. The biggest challenge was manufacturing the internal funnel in the threaded area where the tank was sealed. They successfully controlled the wall thickness in the required areas, made specific design adjustments, and produced a plastic body that met the initial restrictions, completing the process 27% faster.

Overall, this new technology allows companies to reduce cycle times, eliminate labor-intensive processes, manufacture unique product geometries with tight tolerances, consistency, and repeatability. Moreover, it can be used for materials that are difficult to process by traditional molding methods.