Robotics and automation to reap benefits from AI

Danish cobot maker offers its views on key robotics trends in 2024

Artificial intelligence (AI) will help to drive the pace of development in robotics and automation. So predicts Anders Billesø Beck, vice president of innovation and strategy for Universal Robots A/S.

As he gazes in his crystal ball for the coming year, Beck also expects:

- Developments in robotics software to enable more sharing and reuse;

- Companies to increasingly fuse information technology (IT) systems with operational technology (OT) systems and use data to improve operations; and

- Logistics to be an area of focus for robotics.

AI is transforming the world of software development, notes Beck, making it cheaper, faster, and more effective. Software is a key component of automation, and with AI, software developers will be able to create more customized and optimized solutions for various tasks and challenges.

Leveraging AI for software development

UR’s Anders Billesø Beck

“If software development has sometimes felt like digging with a shovel,” he says, “the introduction of AI is like bringing two horses and a plough to the process. However, automation expertise will remain a scarce and valuable resource in the process of AI revolutionizing manufacturing.”

Before joining Universal Robots in 2018, Beck served for several years as the head of section for Industrial Robotics & Automation at Denmark’s Teknologisk Institut. His 18-year-old company –– which operates Universal Robots USA Inc. in Novi, Mich. –– continues to grow.

Founded in 2005, the 1,000-employee, Odense, Denmark-based firm introduced three years later what it called “the world’s first commercially viable cobot.” Since then, the company has sold more than 75,000 cobots worldwide while racking up sales in 2022 of $326 million.

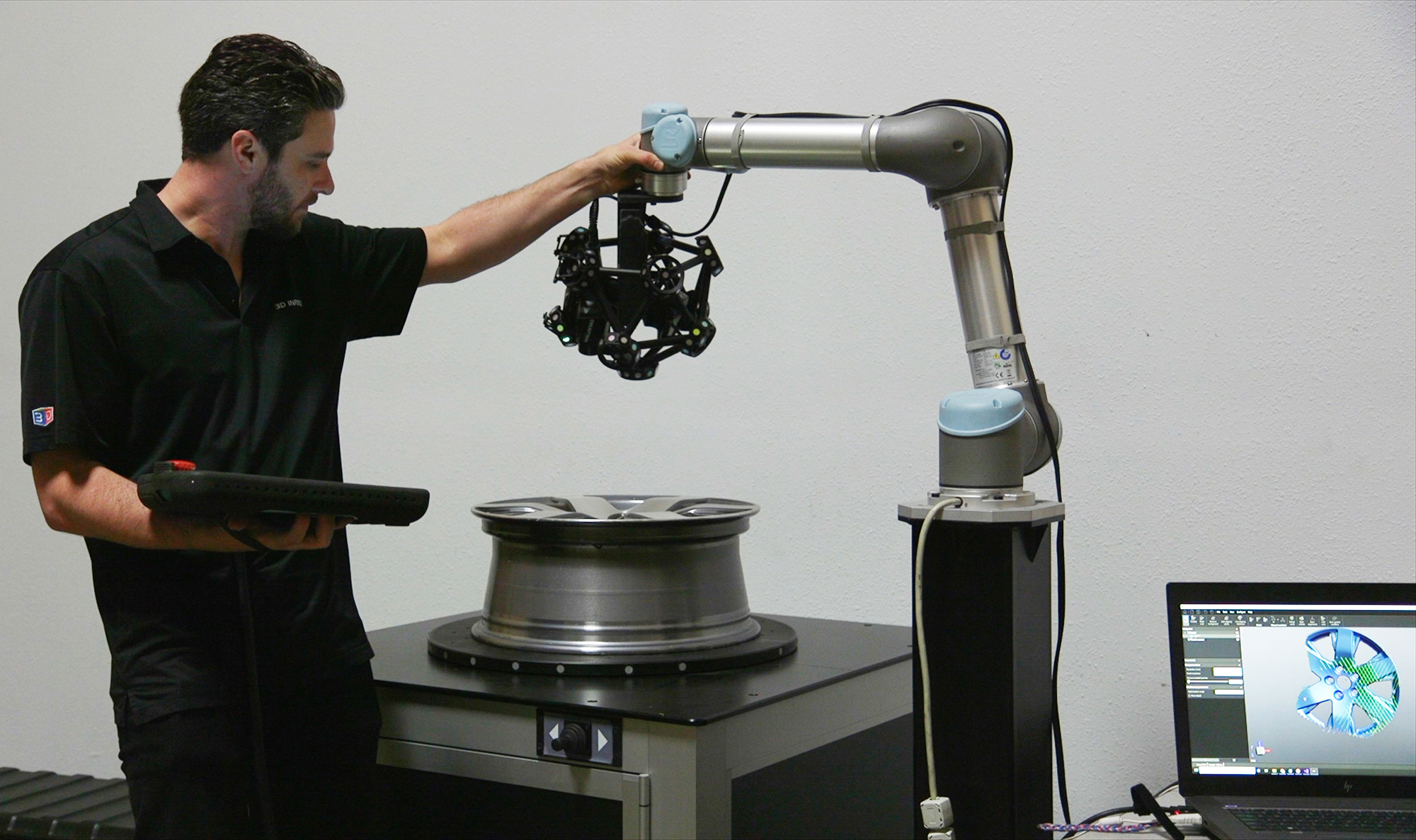

3D Infotech is a UR+ partner developing software designed specifically to run deep learning applications. This embedded solution helps factory automation customers easily solve challenging assembly verification, and defect detection applications that are often too difficult to deploy with traditional, rule-based machine vision tools.

Beck, who has a Ph.D. in robotics from the Technical University of Denmark, said he looks forward to seeing the benefits of AI extending beyond the office and into the factory, with machine learning reaching more manufacturers in 2024.

“After all,” he says, “the technology is already there –– we have many partners developing applications using AI to allow our robots to perform more complex and diverse functions.” For example, AI already allows robots to have human-like perception, handle variation, move parts precisely, adapt to changing environments, and learn from their own experiences.

Increasing collaboration

Beck sees software developments enabling a new dimension of collaboration by connecting the people who use robots. Advances in this space are likely to lead to new levels of sharing and reusability, helping to streamline innovation and reduce time-to-market.

Logistics as an industry is expected to see a 46 percent annual growth in cobot shipments from 2023-27. DCL Logistics in California deployed Universal Robots’ UR10e cobot and realized a 500 percent efficiency increase, 50 percent labor savings, a three-month ROI, and 100 percent order accuracy.

Universal Robots refers to its UR+ ecosystem, which now includes more than 300 UR+ partners and over 400 certified UR+ components, application kits and solutions.

Prediction #3 involves what Beck calls the fusing of IT and OT operations. Many still have an outdated view of cloud-based software services as merely serving as a data collector and backup function. “But,” he says, “the real potential and power doesn’t lie in storing data or even in linking machines. The real transformative leap comes when cloud-based software services connect humans and machines and thus help manufacturers simplify complex processes and make smarter decisions.”

Remote access to manufacturing data will enable quick responses to issues and continuous automation improvement. This offers the promise of improved efficiency and reduced downtime through Overall Equipment Effectiveness (OEE) visualization and predictive maintenance. For manufacturers this can also help to boost quality and lower costs.

Leveraging robotics for logistics

Knowing how your cobot performs at all times –– no matter where you are –– enables quick responses to issues and continuous automation improvement. DeAngelo Marine Exhaust in Florida uses an app from UR+ partner Hirebotics’ Beacon to monitor their welding cobot’s production to see how long the arc was on, how much gas and wire is used, etc.

Beck’s fourth prediction underscores the growing importance of logistics as it relates to automation. He cited a report from earlier this year by Interact Analysis that looked at projected growth rates in robot shipments across industries. Logistics stood out as a leading projected growth area. The study projected a 46 percent compounded annual growth rate (CAGR) for cobot shipments from 2023 to 2027.

“Like manufacturing,” he stated, “many logistics companies face serious labor shortages while pressure is increasing as a result of globalization, e-commerce and complex multichannel supply chains. More logistics, warehouse and distribution centers will turn to automation next year to provide services faster and with greater accuracy.

“Robots –– and the smart use of data –– are poised to revolutionize logistics businesses across the whole value chain from incoming packages to outbound logistics.”