Melt Electrowriting for Biomedical Applications

Melt Electrowriting (MEW) emerged in the biomedical and tissue engineering outlook over a decade ago as a method for printing structures on the low micrometer or nanometer scale. But how does it work, and what does the future hold for this technology?

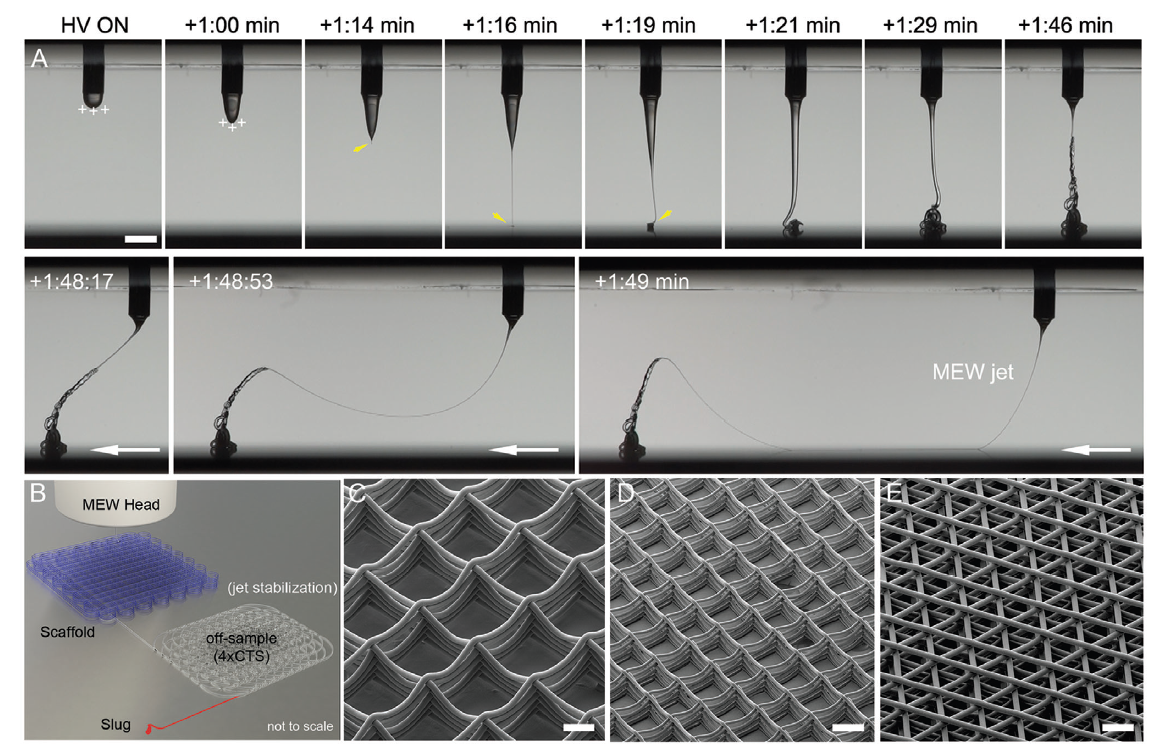

Melt electrowriting is an additive manufacturing technique that involves creating three-dimensional structures by selectively depositing molten polymer filaments onto a substrate using an electric field. In this method, a polymer is melted and extruded through a fine nozzle. Simultaneously, an electric field is applied to guide the deposition of the molten polymer, enabling precise control over the structure’s geometry. As the polymer solidifies upon deposition, layer by layer, complex and intricate structures can be built.

This method is particularly useful in creating scaffolds for tissue engineering, microscale devices, and other applications where precise control over the structure’s architecture is crucial.

How does MEW work?

1. Melted Polymer:

First, MEW starts with a polymer in a melted state, typically heated to its molten phase.

2. Electric Field Application:

Then, an electric field is applied to the molten polymer through a fine nozzle or spinneret.

3. EHD (Electrohydrodynamic) Forces:

The electric field induces charges on the surface of the molten polymer, creating electrically charged droplets or filaments.

4. Precise Deposition:

The EHD forces act on these charged droplets, guiding their trajectory and deposition onto a substrate.

5. Controlled Architecture:

As the molten polymer solidifies upon deposition, layer by layer, the EHD-guided process allows for the creation of three-dimensional structures with controlled architecture.

MEW compared to traditional 3D printing

FEV Vs MEW. Courtesy of Polymers for Melt Electrowriting.

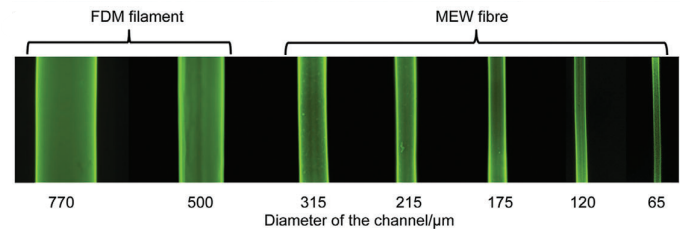

FDM is a filament-based 3D printing process. It normally involves melting thermoplastic filaments and depositing the molten material layer by layer to build a 3D object. MEW, on the other hand, is a more precise process that uses an electric field to draw ultra-fine fibers from a molten polymer. These fibers solidify almost instantly upon deposition, allowing for the creation of intricate structures with high resolution. FDM typically produces thicker layers, resulting in lower resolution compared to MEW. The layer thickness in FDM can range from several hundred microns to a few millimeters.

MEW achieves much higher resolution, creating ultra-fine fibers with diameters in the sub-micron to micron range. This allows for the fabrication of structures with fine details. MEW is often applied in biomedical and tissue engineering applications due to its ability to create highly precise structures at the microscale

Prospects of MEW

The future prospects of Melt Electrowriting (MEW) in the field of additive manufacturing and biomedicine appear promising, with ongoing advancements and potential developments in several key areas such as Tissue Engineering, biomedical implants, Drug Delivery Systems

Also, to enhance the overall capabilities and applications of MEW in the biomedical field, future developments may involve the integration of MEW with other technologies, such as bioprinting or advanced imaging techniques. Additionally, efforts to scale up the production process and introduce automation may increase. This could lead to more widespread adoption of MEW in industrial settings and the manufacturing of medical devices on a larger scale.