From Plastic to Wax: A Technology for Biodegradability

One symptom indicating the need for a reevaluation of the recycling system is the leakage of plastic into landfills and water streams; A British start-up brings a new ingredient to the table: biotransformation from plastic to wax.

If plastic is precious, why would we want to destroy it? This question constantly arises when technologies for biodegradability come to the table. But there’s no denying the truth that recycling, in its current setup, is failing in many parts of the world. A report by Green Peace USA points out that the country’s plastic recycling rate was estimated at 5-6% in 2021, and in Europe, it barely reached 10%.

From plastic to wax

Polymateria, a British start-up born at Imperial College London, recognizes this problem and has developed, as they call it, a technology that can completely biotransform and subsequently biodegrade polyolefins in the natural environment. It functions at the plastic conversion or resin production stage, introduced in low concentrations (less than 2%) into the polyolefin masterbatch, and researchers tailor it to act for the lifetime of the product. It is also compatible with the regular recycling stream, as they have proven with different brands.

How does the technology work?

To activate the biodegradability process, the plastic must be exposed to light, water, moisture, and microbes.

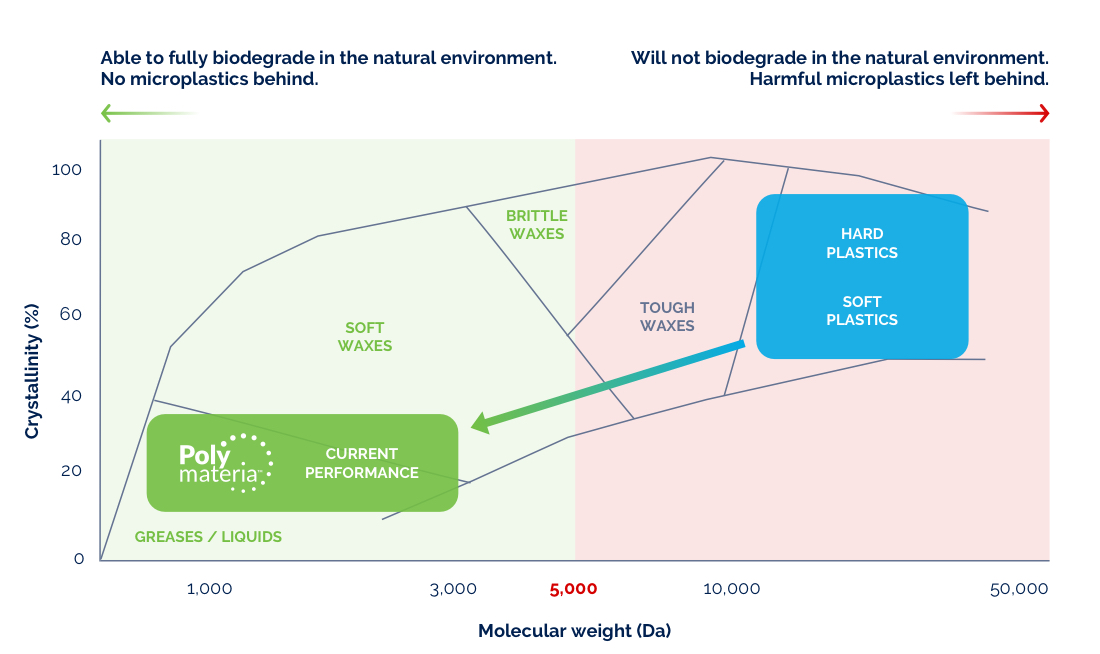

After activation of the technology, chemical conversion causes a rapid loss of physical properties. The technology attacks the crystalline and amorphous region of the polymer structure, rapidly converting it into a wax-like material (low molecular weight) that is no longer plastic and is not harmful to the environment.

Plastic Biotransformation. Courtesy of Polymateria.

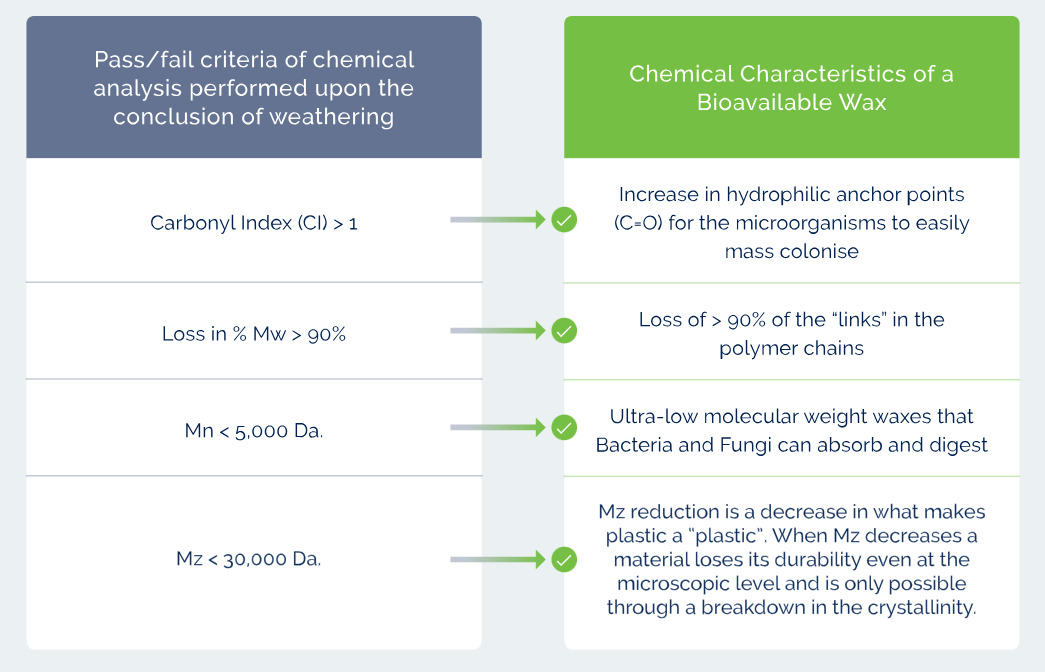

To qualify as such, these waxes must also meet different standards:

Polymateria’s criteria to consider a biotransformation from plastic to wax. Courtesy of Polymateria.

In a natural environment, the weathering phase typically lasts a few months, but in the laboratory, researchers emulate it through UV (film) or Xenon-arc (rigid) exposure for a few weeks.

- The standards used for UV aging are ASTM D4329 / ISO 4892-3.

- The standards used for xenon arc aging are ASTM D2565 / ISO 4892-2.

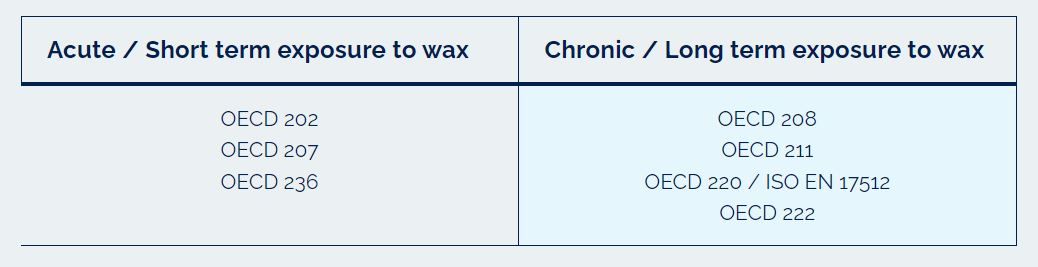

Subsequently, the process of biotransformation takes place, leading to the formation of bioavailable waxes through chemical conversion. Researchers then conduct tests for biosafety in various environmental ecosystems. They examine the acute and chronic ecotoxicity of the waxes in both soil and water.

Acute and chronic ecotoxicity of the waxes in soil and water. Courtesy of Polymateria.

Finally, the bioavailable wax undergoes biological transformation through mineralization by naturally occurring bacteria and fungi in the environment, degrading PE and PP films and rigids within 1–2 years. Third-party labs confirm the complete biodegradation, with no residual microplastics.

Polimateria claims that this technology is able to biotransform polyolefins into a non-toxic wax that will biodegrade. It is important to distinguish these technologies for biodegradability from Oxodegradable additives. As the US and EU banned these for producing microplastics.