The Precision Revolution: Two-Photon Polymerization in Microscale 3D Printing

The marriage of nano- and microscale 3D printing has ushered in a new era of design freedom and efficiency, propelling groundbreaking innovations in micro-optics and micromechanics. These advancements not only drive new developments but also set the stage for technological progress, leading to the increased commercialization of 3D printing techniques tailored for micro- and nano-objects. At the forefront of this transformative wave is the crucial process of two-photon polymerization (2PP).

Often abbreviated as 2PP, this advanced additive manufacturing technology has become synonymous with precision and intricate design. Developed in 1997 by Shoju Maruo, Osamu Nakamura, and Satoshi Kawata at Osaka University, 2PP operates under the microscale 3D printing umbrella, offering unparalleled capabilities for crafting micro- and nano-structures. Since its inception, numerous companies have continued to refine and commercialize the technology, bringing their cutting-edge equipment to market under various patented names.

At its core, two-photon polymerization relies on the principle of photopolymerization. Here, targeted exposure to light triggers the polymerization of synthetic resins, causing molecules to bond and harden, resulting in intricate 3D models. While similar to stereolithography, 2PP distinguishes itself through its interaction with photons. Visible or infrared laser radiation is used, and the term “two-photon” is derived from the simultaneous absorption of two photons, a process critical for the material’s solidification.

In two-photon polymerization, the laser “writes” a structure and pattern in the liquid resin. Courtesy of Heidelberg Instruments

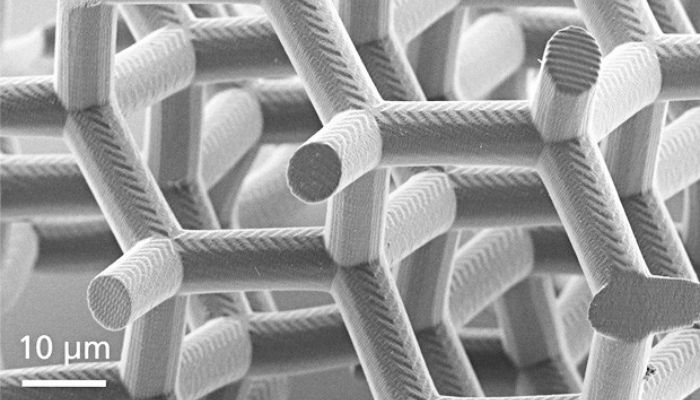

This highly precise process allows for the creation of complex 3D microstructures and nanostructures with resolutions as fine as 25 nm. The technology’s ability to cure specific spots within a focal volume sets it apart, offering design freedom without layer-by-layer limitations. After exposure, post-treatment with solvents removes unexposed liquid resin, leaving behind parts with exceptional precision.

While 2PP’s meticulous approach may result in longer production times for macroscopic prints, its prowess shines in the micro and nano range. The applications of two-photon polymerization are vast, spanning micro-optics, micromechanics, medical scaffolding, and even drug delivery systems. Materials range from traditional epoxy resin and photoresists to hybrid polymers, enhancing stability.

Leading the charge in two-photon polymerization 3D printing systems are manufacturers such as Nanoscribe, UpNano, Microlight, Multiphoton Optics, and Moji-Nano-Technology. These companies not only provide cutting-edge printers but also develop their materials, tailoring them to specific applications, further expanding the versatility of 2PP.

In conclusion, two-photon polymerization stands as a beacon of precision in the microscale 3D printing realm. Its ability to create intricate structures with nanometer precision opens doors to a multitude of applications across various industries, from micro-optics to medical advancements. As the technology continues to evolve, it promises to reshape the landscape of micro-manufacturing, contributing to exciting developments in the plastics engineering industry.