Identification of Polymer Behavior from Nonequibiaxial Elongation Test

In the world of plastics, the quest for perfection is a relentless one. Plastic bottles, ubiquitous in our lives, may appear simple, but their creation is a complex dance of materials and processes. At the heart of this intricate ballet lies the behavior of polyethylene terephthalate (PET), a plastic polymer central to the industry.

Understanding how PET responds when subjected to the stretch blow molding process, a cornerstone of bottle production, has long been a challenge. Unlike metals or other materials, PET doesn’t behave uniformly in all directions, and this non-uniformity is a puzzle that researchers have sought to unravel.

To crack the code, we turned to a cutting-edge approach—an anisotropic visco-hyperelastic (VHE) model. This sophisticated model delves deep into PET’s behavior, providing insights that were previously hidden. It’s akin to looking at a common rubber band and understanding how it reacts when pulled in different ways.

The journey involved a series of intricate tests, where they stretched PET in multiple directions, pushing it to its limits. The goal was to uncover how factors like temperature and the speed of stretching impact PET’s properties.

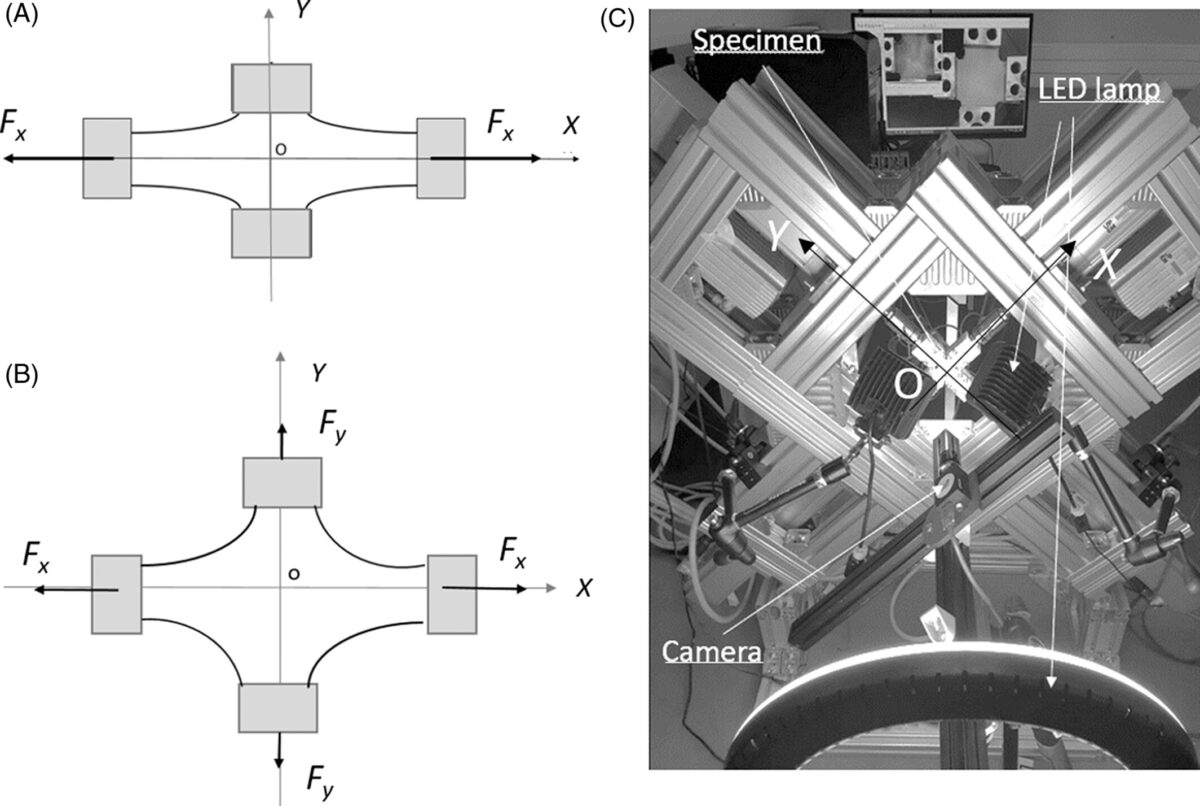

But their quest didn’t stop there. They raised the bar by introducing a specialized biaxial elongation apparatus, a true marvel of innovation. This advanced machine allowed them to fine-tune their model, enhancing its precision and reliability. It was a journey of trials and experiments, aimed at collecting data that would elevate the model to new heights.

However, like any scientific journey, theirs had its share of challenges. They encountered variations in their data—puzzling deviations that needed solving. But science is all about problem-solving, and they dug deep to uncover the sources of these variations. The result? A refined model, more accurate and powerful than ever before.

So, why does all of this matter? It matters because it has the potential to revolutionize the way we manufacture plastic products, particularly those familiar plastic bottles. By peering into the very heart of PET’s behavior during the manufacturing process, we’re unlocking the door to greater efficiency and better end products. The bottle on your table may seem simple, but it’s the result of an incredible journey of precision and innovation.

To read the full report, go to Polymer Engineering and Science Journal, published by SPE.