RadiciGroup Promotes Circularity of Its Nylon Cycling Bibs

Five companies in Bergamo, Italy, partner to turn used apparel into motorbike handguards

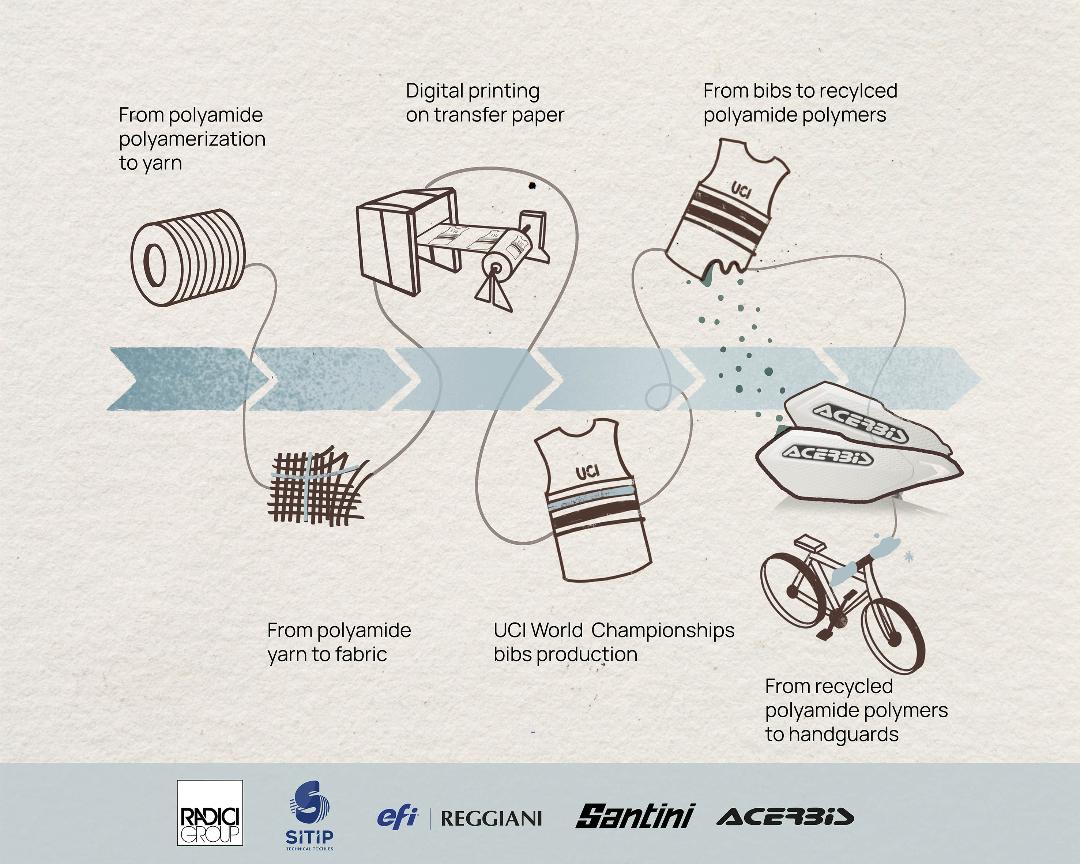

Nylon resin and fiber producer RadiciGroup is teaming with several other northern Italian companies to help a cycling organizer make the upcoming UCI Cycling World Championships in Glasgow and across Scotland a bit “greener.” The bibs that will be worn by event staff and accredited photographers throughout the Aug. 3-13 event are made of a customized nylon fiber made by RadiciGroup and specifically designed for a second life.

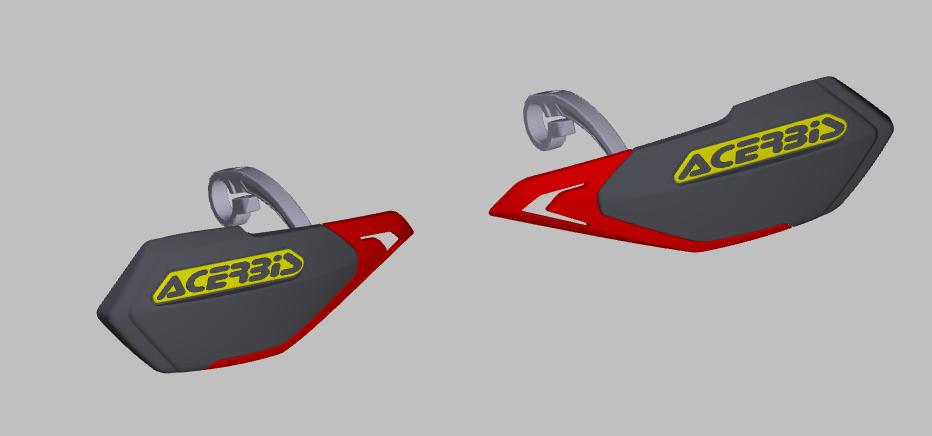

After the race, the used bibs will be returned to Radici, which will process them into new material. Another partner, Acerbis Italia SpA, then will use the repurposed resin to create its X-Elite handguards for mountain bikes. Acerbis touts its molded handguards as thermoplastic, lightweight, compact and crash resistant. Their handguards are attached to the handlebars of some mountain bikes to protect the riders’ hands and shield the brake levers during falls.

Cycling Body Strives to Reduce Waste

RadiciGroup formulated the nylon for use in the yarn used to make the bibs.

This effort is part of a larger environmental initiative by the Union Cycliste Internationale (UCI), the sport’s 123-year-old, Switzerland-based governing body. Last year the group released its UCI Climate Action Charter, which lays out an action plan to advance the environmental sustainability of the sport with a specific principle to reduce waste and accelerate the transition to a circular economy.

To optimize production for the upcoming event, RadiciGroup aimed from the outset to make “circular” bibs using comfortable, recyclable Italian nylon yarn. The firm says it leveraged its expertise in the field of chemistry to create these products, working alongside the other partners. The bibs needed to allow for high-quality printing while also being customizable.

Five partners collaborated to make this apparel fully recyclable, with plans from the beginning for it to have a second life in a different application.

RadiciGroup provided the mono-material, all-polyamide yarn to Sitip SpA to create the “ARAS NG” warp-knitted fabric (95 grams per 100 square meters). Said to be the first nylon of its kind, the fabric was designed to meet the transfer printing needs of EFI Reggiani, the third project partner, as well as RadiciGroup’s recyclability standards.

EFI’s Eco-friendly Inks Used on Organic Cotton Bibs

Recycled nylon bibs are to be molded by Acerbis into handguards for mountain bikes.

EFI Reggiani tested a range of fabrics to find the best color results and best resistance to rubbing and perspiration, which is vital for the bibs’ intended use. In addition to using new Global Organic Textile Standard-certified IRIS Plus water-based inks, digital printer EFI Reggiani chose to print on transfer paper that does not consume water and requires a minimal amount of energy per square meter.

Finally, cycling clothing maker Santini Recycling Wear received both the white fabric from Sitip and the transfer paper printed by EFI Reggiani, and then transferred all the graphics for the 2023 UCI Cycling World Championships bibs from the paper onto the fabric. Santini also took care to assemble the garments using only thread and components made from nylon or chemically similar materials, allowing the bibs to enter the recycling process at their end of life without further processing.