Multi-material 3D Printer Enables Printing of Flexible Electronics

Multi-wavelength, high-power lasers key to printing flexible, stretchable circuits

Scientists in Singapore have developed a 3D printer that prints multiple materials to help enable the production of smart, flexible and wearable electronic devices. Multinational manufacturer Jabil Circuit Inc. already is planning to use the technology to integrate 3D-printed graphene-based electronics into a smart infusion system.

Japanese electronics firm Panasonic is involved in the project, along with scientists from Nanyang Technological University Singapore (NTU Singapore) and the Singapore Centre for 3D Printing (SC3DP). The new multi-material 3D printer incorporates multi-wavelength, high-power lasers that allow the printing of flexible electronics.

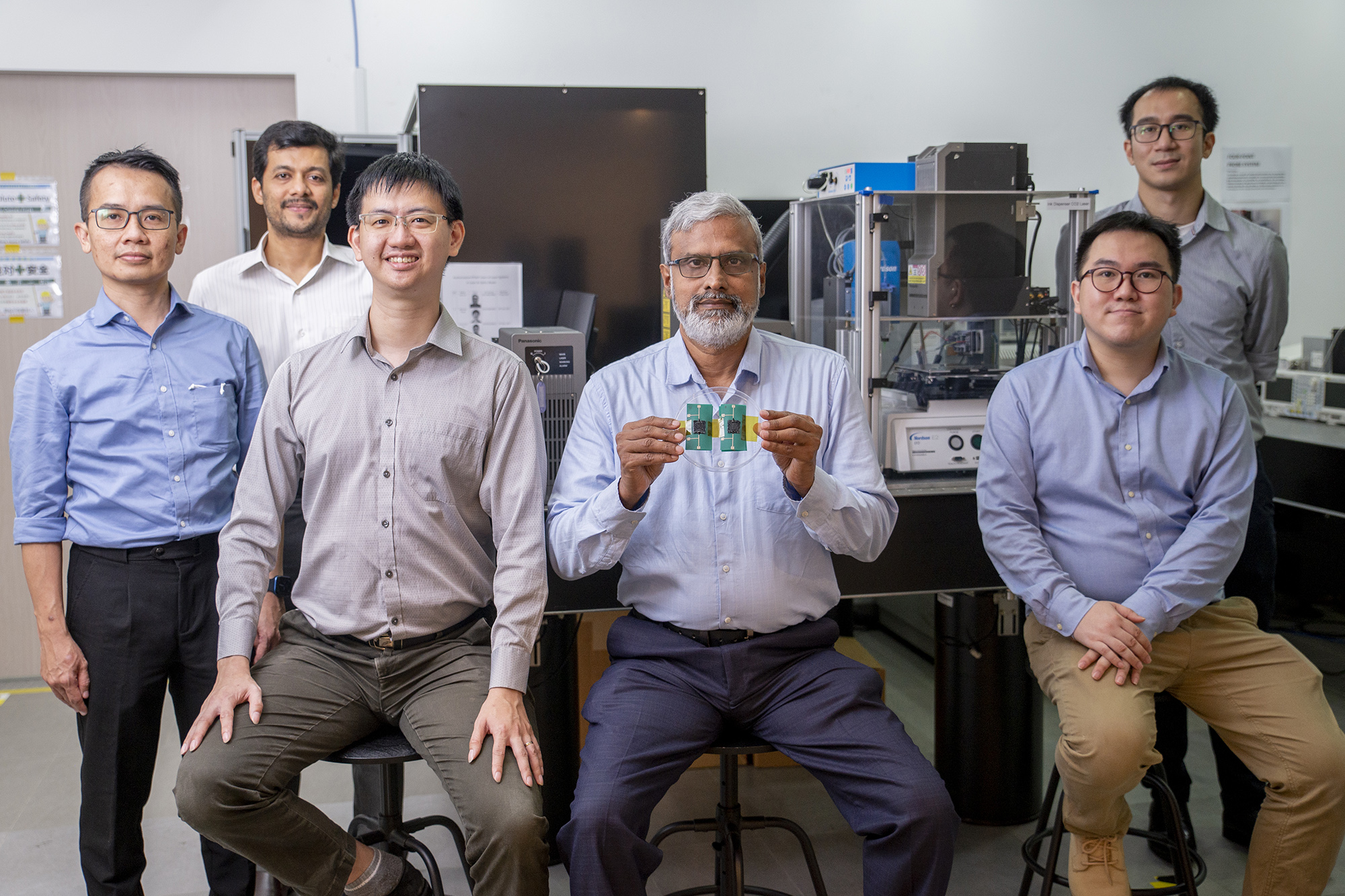

Multi-material printer team includes (from left) Dr. Low Mun Ji, general manager, Panasonic; Dr. Suchand Sandeep, research fellow, NTU School of Mechanical and Aerospace Engineering (MAE); Dr. Nicholas Tham, senior research engineer, Panasonic; Co-leader and associate professor Murukeshan Vadakke Matham, NTU School of MAE, Singapore Centre for 3D Printing; Dr. Joel Lim, research engineer, Panasonic, and Daryl Lim, research associate, NTU School of MAE. Murukeshan holds a sample of a 3D-printed stretchable pressure sensor. Courtesy of NTU Singapore

“Our project aims to find a way to 3D-print new materials like organic polymers and carbon-based materials like graphene, which have properties that allow them to be printed or coated onto flexible substrates like plastics or fabrics, creating flexible and stretchable circuits,” says project co-lead Murukeshan Vadakke, an associate professor from NTU School of Mechanical and Aerospace Engineering (MAE) and SC3DP.

Creating Comfortable, Flexible Electronics

“3D-printed flexible electronics pave the way for more comfortable and mobile wearable devices as they can be lighter and smaller,” he adds. “We can create unique structures that were previously impossible with traditional rigid electronics.”

The project between NTU and Panasonic dates back seven years. The parties describe the technology as follows:

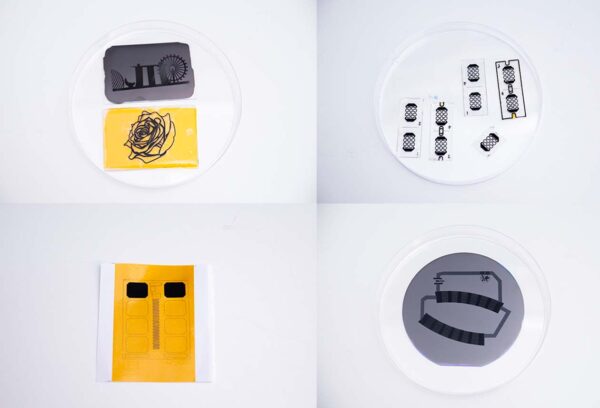

3D-printed graphene structures on glass and flexible rubber substrates (top row). A pre-design graphene layer on a paper and silicon base (bottom). Courtesy of NTU Singapore

“The multi-material 3D printer employs varying laser wavelengths. These trigger thermal and chemical reactions that transform common carbon-based materials, like polyimide and graphene oxide, into a new type of highly porous graphene. Structures 3D-printed with this novel graphene are light and conductive. They can also be 3D-printed or coated onto flexible substrates like plastics, glass, gold and fabrics, creating flexible and wearable devices.”

Panasonic has already created a facility for laser-based manufacturing systems at its research hub in Singapore. This will enable further trials of concepts using components 3D-printed by the multi-material printer. These efforts are part of Panasonic’s “Autonomous Factory” concept, designed to help inform its smart factories of the future.

Jabil Uses Concept on IV Fluid Bag

A Penang, Malaysia-based unit of Jabil, meanwhile, said it has demonstrated a proof of concept through a prototype of a low-cost IV fluid bag with an embedded printed sensor powered by artificial intelligence. The device monitors the status of the IV drip, regulates parameters such as pressure flow and temperature, and transmits the information to a smartphone in real time. This allows medical personnel to remotely monitor, control and detect abnormalities efficiently.

Dr. Low Mun Ji, Panasonic general manager and co-leader of the project, adds: “Our technology allows the creation of highly porous and conductive graphene-based material for use in different applications. Compared to traditional graphene manufacturing methods, our method is faster, cheaper and highly compatible with a wide range of materials.”