Making and Preserving History: Glenn Beall Lives and Makes Plastics History

Industry icon Glenn Beall stamps an indelible legacy on the growth of plastics and of SPE

Recently, I had the privilege of spending a day with Glenn Beall, who joined SPE in 1960 and is the Society’s oldest active member.

My husband, Mark Richardson, also an engineer in the plastics industry, took the road trip with me to Libertyville, Ill., where Beall lives. We started the day early at one of Glenn’s favorite restaurants where everybody knew his name. As we were catching up, he handed me his 18-page curriculum vitae. His long list of accomplishments made it difficult to pick a starting point for the interview. He’s not only an engineer, but an entrepreneur and business owner (he started two companies, Glenn Beall Engineering and Glenn Beall Plastics Ltd.), a successful consultant, an educator (he taught plastics technology seminars for SPE, nine colleges and universities, and seven major corporations), an inventor, an author (four books—two still in print), an editor (nine different publications), a columnist, an industry expert, a Plastics Pioneer and a mentor (his favorite SPE memory is about mentoring; more on that later).

That edited list of achievements is highlighted by his leadership in SPE. He is one of only six Distinguished Members in the history of the Society who did not serve as SPE president. This is the most prestigious honor offered by SPE and is awarded when two-thirds of the past presidents deem a candidate worthy. He has served on various national committees and garnered numerous awards. He founded the Product Design and Development (1989) and Rotational Molding Divisions (1996) and still sits on those boards, has served on the Medical Plastics Division board, the Mold Making and Mold Design Division board and was recently elected to the Milwaukee Section board (2020). But it all started in Chicago.

“There was this guy at college who came back from the Korean War and hooked me on this idea of plastics, so when I got my first job at General Electric, I read everything I could.”

In 1958, Beall lost his job with GE and was looking for a position to learn more about plastics. He wound up at Abbott Laboratories. They were looking to design and develop drug delivery systems, which historically used reusable materials such as phenolics, glass and gum rubber. During World War II, the plastics industry had learned how to make affordable products to use once and throw away and Abbott wanted to go disposable. “I didn’t know very much about plastic, but I could talk about plastic, so I got the job,” he said. At that time Abbott was doing injection molding, blow molding, thermoforming, compression molding, extrusion, calendering and all kinds of heat welding, so he had the opportunity to gain experience with those processes. After a couple of years, he got noticed by the department manager for being an active learner. “He would give me an article or a book, and I got to know him. One day he invited me to an SPE conference in Chicago. My registration bought a one-year membership and my boss told me I’d be invited to the monthly meetings, and he wanted me to go. He also informed me that I had to pay my own dues from then on because SPE wasn’t on the list of approved organizations for Abbott.”

SPE turned out to be a fruitful opportunity because instead of being a young engineer buried deep in the lab where he could only interface with his colleagues and a few suppliers, he was exposed to the entire plastics industry. He said SPE was thriving in those days—meetings were a “mob scene” with 200 to 300 people, many who were experts. “I’d take a problem to the meeting and come back with a solution and soon I had people at Abbot bringing me jobs to take to Chicago SPE to get free consulting. I learned something every single time,” Beall remarked.

Eventually he was elected to the SPE Chicago Section board. He looked around the table at his first meeting as a director and wondered what he was doing there sitting with the titans of the Chicago plastics industry. “And then there was me, I didn’t think I belonged there,” he remarked. They were passing out committee assignments and came to the newsletter. His mentor, Jack Glatt, raised his hand and volunteered him for the job.

After the meeting Beall protested, “I can’t type, I can’t spell and I never wrote anything anyone wanted to read, but Jack set me straight with the facts.” The newsletter would go out every month with Glenn’s name and picture and in six months everyone would know who he was, and, in a year, they would have decided that if he knew enough to be the newsletter editor, then he must be an important person. It worked.

In 1967 he became president of the Chicago Section, which was one of the largest at the time, and that gave him contact with SPE’s national office and more opportunities for volunteering and getting to know the “big guys” in the industry, all the while not realizing he was becoming one of those “big guys.”

We finished the last of our diner coffee and headed to his office so I could gather more stories from the man who admits he learned nothing about plastics while getting a mechanical engineering degree from Bradley University, class of 1957.

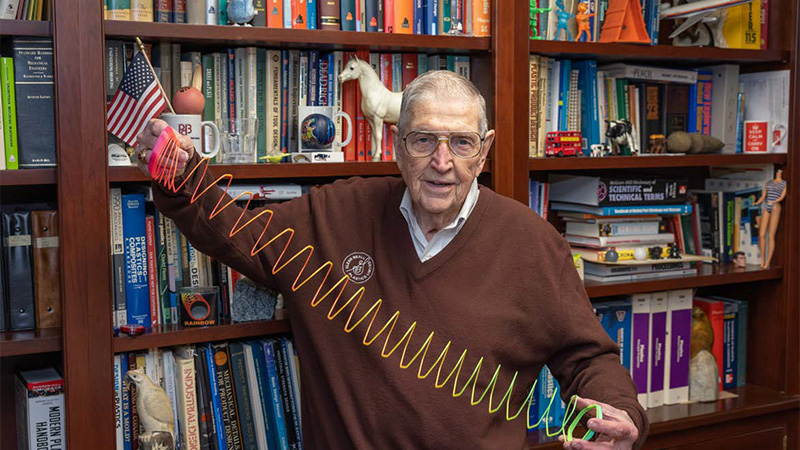

His office reception area has 35 patents on display, ranging from one as simple as “container” filed in 1958 when he was a fresh engineer to “gas generating apparatus for anaerobic atmosphere” filed in 1981. Moving through a long room lined with cabinets filled with historical articles and files, I couldn’t help being impressed with the number of mementos, certificates and trophies commemorating his illustrious career.

We sat in a room with a display cabinet that holds hundreds of plastic treasures, including antique celluloid clocks and billiard balls, and a colorful plastic Slinky toy. I asked which item was his favorite, and he answered, “Whatever has my interest at the moment.” On that day, it was an object in the Plastics Collection at Syracuse University—a plaque of Giuseppe Garibaldi, a 19th century Italian general and revolutionary and a force behind the unification of Italy. The artifact was compression molded of Bois Durci, a natural plastic made from very fine sawdust and blood from the Paris slaughterhouses. Patented in 1856 by Francois Lepage, Bois Durci is a dense material that can be worked and polished and was important for the manufacture of decorative items until it was replaced, according to Beall, by phenolics and celluloid. The Plastics Collection at Syracuse was a project he spearheaded working through the Plastics Pioneers Association (PPA) History and Artifacts Committee to make sure the industry’s history would not be lost when the National Plastics Center and Museum of Leominster, Mass., closed in 2008. (Information about the plastics collection and efforts of the PPA to preserve it is at https://plastics.syr.edu.)

Beall’s office includes a long room with cabinets full of articles and files. Trophies and awards are also on display, and on an adjacent wall, not shown here, are 35 of his patents.

When asked about his favorite SPE memory, Beall responded quickly with a name: Vicki Flaris. Glenn was with his wife, Patsy, at an ANTEC in 1992 and saw a young woman standing alone at a networking event. He whispered in Patsy’s ear: “I bet she’s all by herself, go talk to her.” She did and the friendship began; they invited Vicki to the welcome reception. At that time, the banquet was full of pomp and circumstance, and Dr. Flaris was charmed by the evening and the dinner companion Glenn had arranged, George Nelson. After that, the Bealls saw her at every ANTEC. Vicki and Patsy hit it off. “Vicki knew how to talk to people. She was good at that,” he remembered.

When Dr. Flaris became a professor at Bronx Community College, she found donors to finance her students’ attendance at ANTEC, many of them Black and Hispanic inner-city kids who lacked the means to travel. “She always introduced me as some big important person who welcomed her to SPE and then she would count on me to talk with the students, asking them what they wanted to do in the plastics industry, giving advice if I had any,” Beall recalled.

The bigger story, as he told it, was when Vicki ran for SPE president. She impressed him, and for the duration of her campaign he talked to SPE councilors whenever he could, asking them who they were supporting. And then, no matter their answer, he’d pitch Vicki as a great candidate. “You know, you’re a grown up,” he’d tell them, leading them along, “and you can choose whoever you want, but look at this woman. She’s not out there blowing her own horn all the time, and you won’t make a mistake by voting for her.” After a Council meeting that year, someone shared the rumor that Glenn Beall was promoting Vicki Flaris for president. Glenn’s face lit up when he told me the story and exclaimed: “Great, I couldn’t have done better, and I’ll be damned if she didn’t win.” Dr. Vicki Flaris, who passed away in 2019, was only the fourth female president of SPE, in 2007 to 2008. “She was a winner. She volunteered for stuff and not only that, but she did what she said she would do. You find someone like that and you put your arms around them.”

When I started working for the SPE Foundation in 2016 I was told to meet Glenn Beall, because everyone knows Glenn and Glenn knows everyone. “That was the seminars,” he said when I shared his reputation with him, “we ran them from 1973 until 2008 and I got to know a lot of people.”

According to Beall, in the 1960s SPE was doing a fantastic job at plastics education, except for product design. “Young engineers were coming out of college and designing plastic parts like they were metal parts, and it just wasn’t working. I made a lot of money as a consultant sorting it out,” he said. “There are remarkably simple rules you can follow when designing plastic parts. After World War II, the big resin manufacturers recognized that the pent-up consumer demand for products was going to result in a major market. A lot had been learned during the war, but it was scattered throughout the trade literature.” Since there didn’t seem to be a cohesive plan for this type of education, Beall set himself up to quantify and qualify what was known about plastic product design. “I started accumulating brochures and information about how to process resin. To capitalize on the demand, someone had to teach the processors how to do it and stop burning the darn stuff up.”

When he started his business, customers brought designs they wanted to make out of plastic, asking what the best material would be. He’d make a recommendation based on what their competitors were doing. When they would ask where to find the material, he would tell them he didn’t know, and he had to look it up. “And now I’ve got them on a hook for some more work.” Eventually he was asked to help with processing and design, too. He was regularly getting requests to deliver educational lectures and realized if he could stand up for six-and-a-half hours instructing a room full of engineers and technical folks about how to manage design and processing, they’d think he knew what he was doing, and he’d get more business. “That’s how the seminars came about. It was a method of selling.”

And that is my legacy to SPE, Beall said. “Over 30,000 people attended my lectures and seminars. You see a guy in the audience when everyone else is getting ready to go to lunch. He’s flipping through the handout, a look of curiosity on his face because I happened to hit on a problem he’s having. I think, ‘Hey, I got one,’ and I perk up a bit. Then I elaborate on the subject a little more than usual and he’s going back to the office and telling his guys about a seminar where he learned what they needed to do—some of ‘this’ and ‘that’ and ‘whatnot’ to get a good part.

“He then tells his boss that he believes the guy—that’s me—and that sharp corners in a mold impede the flow of plastic and create molded-in stress, and that’s why the company’s products lost their impact strength. ‘Well, I’ll be darned,’ the boss says, and calls his moldmaker to get the problem resolved. In one short session I’ve made a difference in a way they won’t forget.”

This sounds straightforward, but it also seems as if Glenn Beall’s legacy has a breadth and depth to it that can’t be expressed in a few short pages. I can list his business successes and contributions of time, talent and treasure to dozens of organizations, but what is impossible to list is how he has influenced the people who have been privileged to move in his circle. He’s one of those guys who has been around for what seems like forever, and many of us (you know who you are) have a story or two about how he’s made a positive impact on our lives and careers.

Maybe it’s the fun he seems to have whenever you get in the weeds about plastics design and processing, or how you can see his brain working to put together the puzzle of how everyday objects fit into the history of plastics. Or maybe it’s how he recognizes the role and importance of relationships. One that is legendary and revered is Glenn’s partnership with his wife, Patsy, who passed away in 2014. Beginning in 1968, the year they started their business, they worked together tirelessly as professionals creating success and as volunteers supporting the plastics organizations they loved.

That nurturing energy for the people and for the success of the plastics industry is the true legacy for all of us. Thanks, Glenn.