Datwyler Adds High-Tech Sealants for New Mobility Vehicles

Datwyler, a manufacturer of system-critical polymer components for diverse industries, is expanding its in-house capabilities with an initiative called Project ETEMI, an acronym for electrically and thermally conductive and electromagnetic interference (EMI) shielding materials.

Battery packs can be enhanced with thermally conductive elastomer sealing materials developed by Datwyler. Sealing gaskets applied to a pack could provide structural stability and environmental protection, as well as heat transfer from the battery. Images courtesy of Datwyler

The Schattdorf, Switzerland, company is using the program to address engineering challenges in new mobility applications like hybrid and battery electric vehicles, through materials development in thermoplastics, elastomers and liquid silicon rubber. Much of the work is focused on sealing technologies, which will give product developers materials that provide enhanced functionalities such as the ability to sense seal integrity or keep electrical charges in a battery gasket.

Datwyler envisions the ETEMI project as a catalyst for development of a materials matrix whereby electrical and thermal conductivity and EMI shielding can be coupled and decoupled to suit application needs. The thermal management of an electric vehicle battery could be managed in part by its sealing material, for example, while EMI shielding can be introduced via sealing technology to safeguard sensors and other critical controls from environmental effects as well as EMI.

Electrical conductivity for discharging and antistatic materials is also possible via sealing technology, and the company says this combined functionality will enable certain components to be removed—such as metal conductors—thus enabling weight-reduction benefits in vehicles. Overall, a key objective is to balance the ability to provide a high-performance seal with the need to meet additional requirements from electrification.

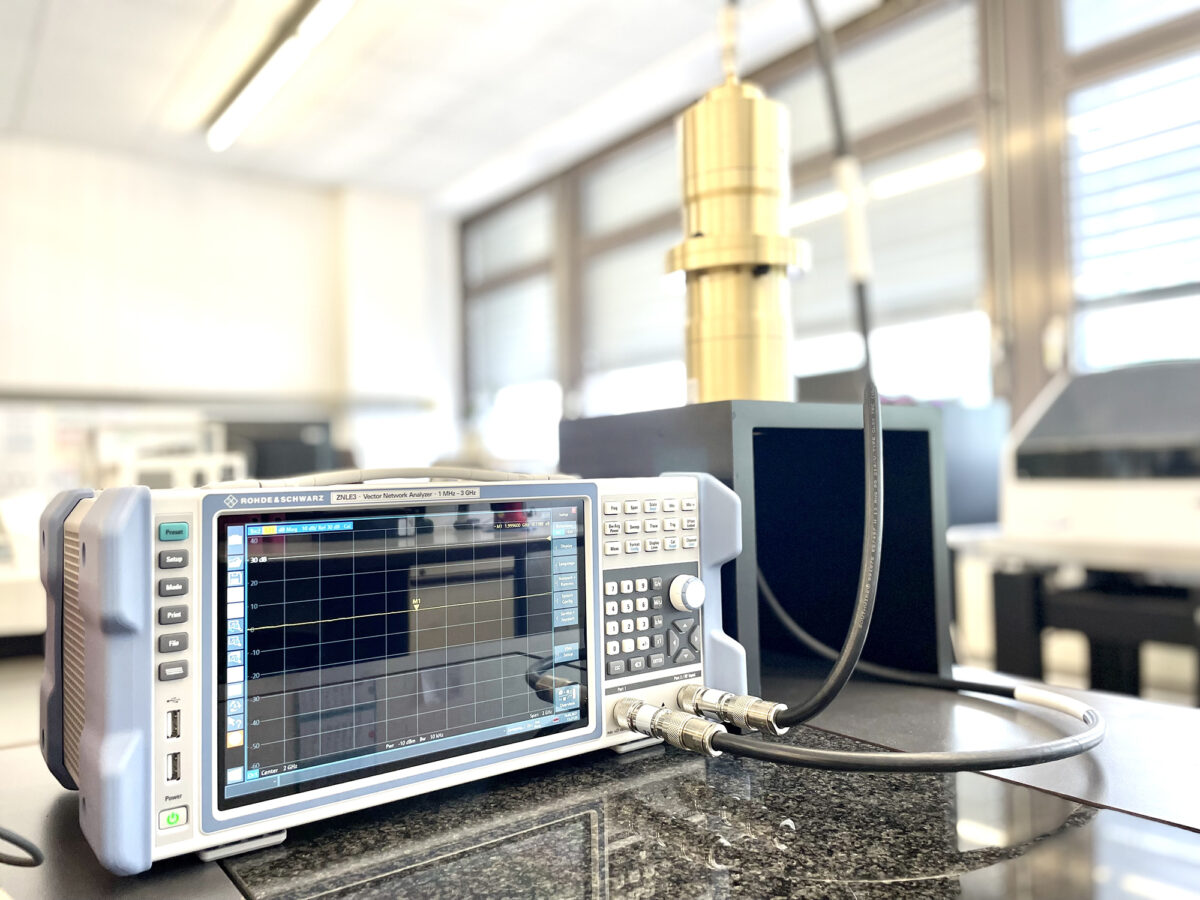

Datwyler officials say the company’s capabilities are advancing in many areas as a result of the project. These include the in-house formulation and mixing of high-performance compounds and the ability to comprehensively analyze and test new materials.

Many of the challenges encountered as electrification projects develop will be new to most engineers, and materials in this space must comply with regulations that are evolving and more stringent than before. As a result, Datwyler is equipping its in-house laboratories with the types of technology required to develop and test compounds to the highest levels of regulated norms, such as ISO 1853 and ASTM D911 for conductivity, ASTM D4935-18 for EMI shielding effectiveness or DIN EN 993-15 to characterize thermal conductivity of compounds.

“As the trend towards electrification gathers momentum, the ability to conduct electricity and heat, as well as to shield certain components from electromagnetic signals, is increasingly important,” says Luana Lettieri, manager of material development. “Project ETEMI is the driving force behind an entirely new category of materials that will meet the highest requirements of sealing technology.”